If you work with electrical installations, solar PV, utilities or manufacturing in India, knowing the Indian Standards (IS) that govern cables is vital. This guide explains what each standard covers, which types of cables fall under it, the lab equipment you need to test to the standard, who (major manufacturers) makes cables to these standards, and where you can procure the test instruments. Use this as a how-to resource: learn practical tips, examples, and a checklist for compliance and lab setup

Indian IS standards:

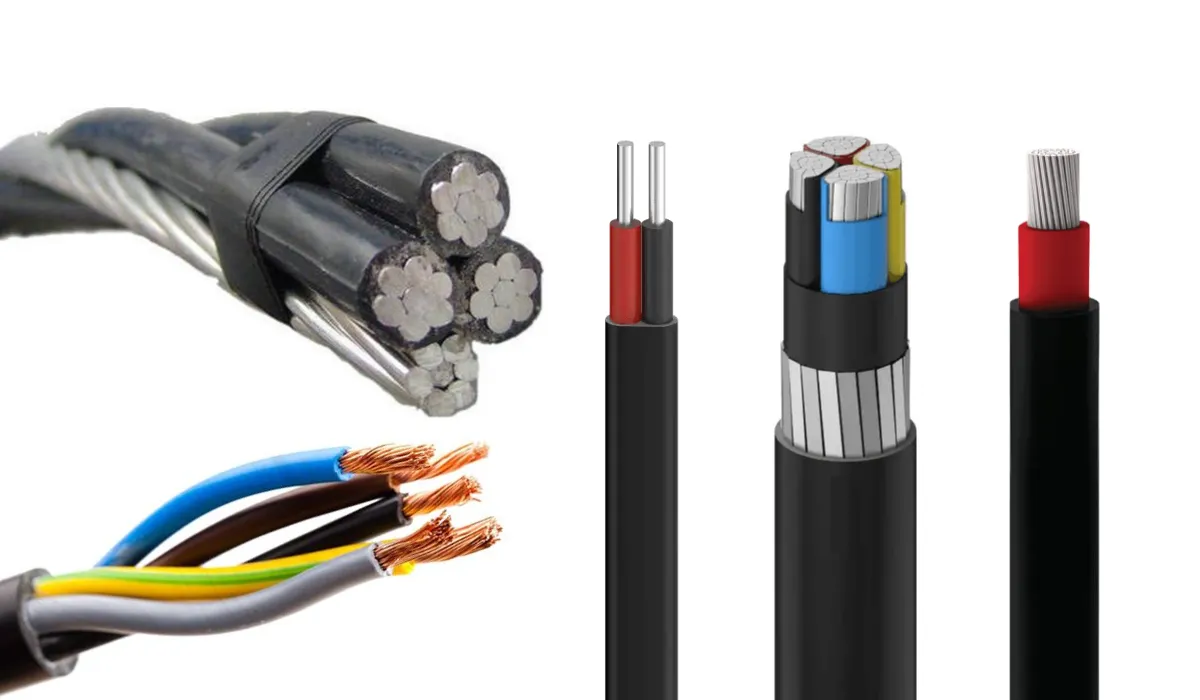

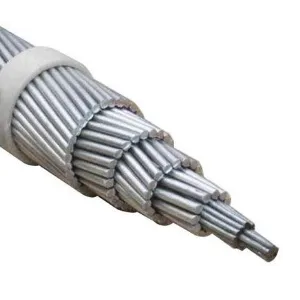

IS 398

Aluminium Conductors / Overhead Conductors

What it covers: Stranded aluminium conductors (various grades and constructions) used for overhead transmission and distribution (nominal aluminium area up to specified limits). Typical examples: bare aluminium stranded conductors for overhead lines and conductors for service and distribution.

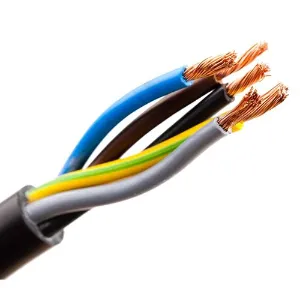

IS 694

PVC insulated unsheathed and sheathed cables/cords for voltages up to 450/750 V (and variants up to 1100 V)

What it covers: Single- and multi-core PVC-insulated, unsheathed and sheathed cables and flexible cords for rated voltages up to and including 450/750 V (and product manual references extend to 1100 V ranges for heavy duty variants). Typical: house wiring, power cords, building cabling, light and fan cables

IS 1554

PVC insulated (heavy duty) electric cables (Part 1 up to 1,100 V; Part 2 for higher voltages)

What it covers: PVC insulated heavy-duty electric cables. Part 1: up to and including 1,100 V (LV heavy duty). Part 2: medium voltage ranges (3.3 kV to 11 kV) — for industrial feeders, armoured cables and higher duty power distribution

IS 7098

Cross-linked polyethylene (XLPE) insulated thermoplastic-sheathed cables (series; Part 1, Part 2)

What it covers: Cross-linked polyethylene (XLPE) insulated thermoplastic-sheathed cables for power distribution; covers multiple parts for different voltage classes (LV, HV, etc.). Typical: power distribution feeders where XLPE insulation is preferred for higher temperature rating and improved electrical properties

IS 14255

Aerial Bunched Cables (ABC) — insulated conductors over a messenger for overhead distribution (up to 1,100 V)

What it covers: Aerial bunched cables — insulated conductors twisted over a messenger wire for overhead distribution up to 1,100 V; used as an alternative to bare conductor overhead lines in urban/lean tree areas to reduce faults and improve safety. Example: three-core ABC for street lighting or feeder distribution

IS 17293

Solar PV (photovoltaic) cables (covers PV-rated cables up to 1,500 V DC, conductor/insulation/UV/thermal requirements)

What it covers: Cables specifically for PV systems — single-core flexible tinned copper conductors, XLPO/XLPE insulation and UV/stress resistant designs rated up to 1,500 V DC. Designed to survive outdoor, rooftop, and long-term solar installations (20+ years expected life)

Lab & test equipment needed (What & How to set up)

Below is a compact, practical table listing the typical laboratory equipment / instruments required to test and certify cables against these IS standards. The lists follow the test-equipment annexes and product manuals in BIS guidance (manufacturer/lab product manuals specify required testers; see citations under each standard). Use this as a starter checklist for a QC or compliance lab.

Tip: many BIS product manuals include an ANNEX – B listing “List of Test Equipment” — use those lists as your authoritative checklist for accreditation/certification

Required instruments per IS standards

| Lab Equipment | IS 694 | IS 1554 | IS 7098 | IS 398 | IS 14255 | IS 17293 |

| Micro-Ohm Meter / Kelvin Double Bridge | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| Insulation Resistance / Meg Ohm Meter | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| High Voltage Tester (AC / DC Hipot) | ✅ | ✅ (higher capacity) | ✅ | ❌ | ✅ | ✅ |

| Conditioning chamber | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Hot Air Oven | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Ageing Oven | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Megohm Box | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| AC Spark Tester | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Hot Set Test Apparatus | ❌ | ❌ | ✅ | ❌ | ✅ | ✅ |

| Tensile Testing Machine | ✅ (250kg) | ✅ | ✅ | ✅ | ✅ (higher capacity) | ✅ |

| Impact Tester | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Flammability Test apparatus | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Micrometer / Vernier | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| Profile Projector / Travelling Microscope | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Thickness Gauge | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| Precision Weighing Balance | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| Water Bath | ✅ | ✅ (higher capacity) | ✅ | ❌ | ✅ | ✅ |

| Shrinkage Test Setup | ❌ | ❌ | ❌ | ❌ | ✅ | ✅ |

| Thermal Stability Test Apparatus | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Dumb-Bell Cutting Machine with Die | ✅ | ✅ | ✅ | ❌ | ✅ | ✅ |

| Mandrels (Smooth metal, Heat Shock etc) | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| Water Absorption Test Apparatus | ❌ | ❌ | ✅ | ❌ | ✅ | ❌ |

| Oxygen Index test apparatus | ✅ FR / FR-LSH | ✅ FR / FR-LSH | ✅ FR / FR-LSH | ❌ | ❌ | ✅ |

| Halogen Acid gas Test | ✅ FR / FR-LSH | ✅ FR / FR-LSH | ✅ FR / FR-LSH | ❌ | ❌ | ✅ |

| Smoke Density Test Apparatus | ✅ FR / FR-LSH | ✅ FR / FR-LSH | ✅ FR / FR-LSH | ❌ | ❌ | ✅ |

| Torsion test Apparatus | ❌ | ✅ | ✅ | ❌ | ❌ | ❌ |

| Ozone Resistance Test Apparatus | ❌ | ❌ | ❌ | ❌ | ❌ | ✅ |

A practical guide — which tests are high-priority and why

- Insulation resistance & high-voltage (hipot) tests: Always first for new cables — they catch manufacturing defects and voids. Use a reliable megohmmeter and an AC/DC High Voltage Breakdown Tester as required by the standard. (Essential for IS 694, IS 1554, IS 7098, IS 17293)

- Partial discharge (PD) & tan delta: Critical for MV and XLPE systems (IS 7098 and higher voltage parts of IS 1554). These catch incipient defects that hipot alone may miss

- Mechanical tests (tensile / elongation / conductor stranding): Vital for conductor strength (IS 398, IS 14255) and for flexible PV cables (IS 17293). Have a calibrated tensile machine

- Ageing, UV, thermal cycling: For outdoor-rated or solar cables (IS 17293), simulate long-term exposure (UV and heat) — especially important in India’s climate

Tip: If you’re setting up a small QC lab, prioritize: a calibrated megohmmeter, a reliable hipot tester (AC/DC or VLF as needed), a digital micrometer/gauge, and a tensile tester. Add PD/tan-delta equipment as you scale to MV/XLPE testing.

Who manufactures cables to these standards in India? (Who & Examples)

India has many established cable manufacturers who produce ranges conforming to the IS standards above. Major names you’ll commonly find in the market (and in BIS/industry lists) include:

- Polycab India Ltd. — extensive LV & power cable ranges

- Finolex Cables — strong presence in building wires and power cables

- KEI Industries — power and specialty cables

- Havells — consumer & industrial cables

- RR Kabel — house wiring, power cables

- V-Guard — house wires and specialty products

- Universal Cables, Sterlite, Torrent and others — many produce LV, MV, XLPE and solar-rated cables

How they relate to standards:

- Most large manufacturers list compliance to IS 694 / IS 1554 / IS 7098 / IS 17293 for their respective product lines (house wiring, heavy duty PVC, XLPE power cables, and solar cables). If you need a specific mapping (e.g., which product codes comply with IS 17293), check the manufacturer datasheet or BIS license/product manual for that SKU. For example, PV cables will explicitly state compliance to IS 17293 on datasheets or BIS product manuals

Where to get instruments & test equipment in India (Where & Resource)

If you need test instruments for cable testing — from a simple megohmmeter to MV PD analysers — here are practical sources:

Brands & suppliers (who to contact)

- Megger — global leader for insulation testers, cable fault location, cable diagnostics and MV test equipment. Available via local distributors in India

- Fluke / Fluke Networks — network & cable testers, DMMs; India presence with authorized offices and distributors. Good for copper/fiber/network cable test instruments and insulation testers

- Seaward — electrical safety and solar test instruments (distributors in India handle PV test equipment)

- Indian / local manufacturers & suppliers — companies like Maxwell India and other domestic instrument makers/suppliers provide wire & cable testing instruments (HV breakdown testers, micro-ohmmeters, million-megohm meters, AC spark testers, tensile machines). These local suppliers often provide customization, calibration and quicker service in India

Where to buy & tips (practical)

- Authorized distributors: For Fluke/Megger/Seaward buy through authorized India distributors for warranty and calibration support. (Use the brand “Where to buy” pages to locate local dealers.)

- Specialist cable-test houses / suppliers: Firms that specialize in cable testing (local vendors, established Indian suppliers) can provide instruments and on-site training. Check trade shows and B2B listings

- Local manufacturers for bench equipment: For routine lab equipment (tensile tester, thickness gauge, UV chamber) Indian vendors provide good value and spares/support. Examples include Maxwell India and other Indian instrument manufacturers/suppliers

- Calibration & accreditation: Ensure the instrument supplier can provide calibration certificates and service — this is essential if your lab needs BIS accreditation or ISO/IEC 17025. Ask for calibration traceability to NABL or equivalent.

Practical compliance checklist — a short tutorial (How & Learn)

- Identify which IS standard applies for your cable (voltage rating, conductor material and application: overhead, underground, solar). Example: rooftop PV runs → check IS 17293

- Follow the BIS product manual (look for ANNEX – B: list of test equipment & sampling guidelines). This tells you exactly what tests and instruments are required for BIS certification

- Set up a prioritized instrument list: For example – megohmmeter, hipot, tensile, thickness gauge, micro-ohm meter; add PD/tan-delta if you’ll test XLPE or MV cables

- Ensure calibration & traceability: instruments used for certification must be calibrated and traceable (NABL where required). Ask suppliers about their calibration services.

- Documentation: maintain test logs, calibration certificates and sampling records — BIS auditors and customers will request them.

Common mistakes & tips (Ideas & Tips)

- Mistake: Skipping PD analysis on XLPE/MV cables — results in missed incipient faults

- Tip: Investing in PD/tan-delta testing if you work with MV/XLPE cables

- Mistake: Using an uncalibrated hipot or megger for acceptance testing

- Tip: schedule periodic calibration and retain certificates

- Mistake: Assuming a cable labeled “UV-resistant” meets IS 17293 — check datasheet and BIS compliance

- Tip: always get manufacturer datasheets & BIS license/product manual references

Final checklist — Quick “What to buy / do” (Help & Actionable)

- Determine cable type & applicable IS standard (IS 394/694/1554/7098/14255/17293)

- Read BIS product manual (ANNEX-B) for the authoritative test-equipment list for that standard

- Start with these core instruments: megohmmeter, hipot tester (AC/DC/VLF), micro-ohm/milli-ohm meter, tensile testing machine, micrometer/thickness gauge. Add PD/tan-delta & environmental chambers as needed

- Buy from authorized distributors for Megger/Fluke/Seaward for critical test gear; consider local suppliers (e.g., Maxwell India and other Indian vendors) for bench and specialized cable-test equipment and for faster service

Closing — why this matters (Why)

Compliance with the correct IS standard is not just paperwork — it guarantees safety, product life, and warranty. Proper testing (with the right instruments and procedures) reduces field failures, minimizes safety hazards, and helps earn customer trust. Use this guide as a how-to resource: learn which standards apply, set up a practical test lab, and pick the right suppliers to get your cables certified and market-ready.

Sources / Further reading (official product manuals & suppliers)

- BIS product manual & standards: IS 694, IS 1554, IS 7098, IS 14255, IS 17293, IS 398

- Top cable companies in India (market overview). Heads Up B2B

- Instrument suppliers/manufacturers: Megger, Fluke, Seaward, Maxwell India