Description

Specifications

-

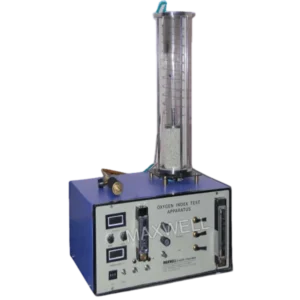

Model: VO-281

- Inner Chamber Size: Diameter 10″, Depth 12″

-

Capacity: approx. 15.5 Litres

-

Standard Compliance: IS:10810 Part 33, IS 7098

-

Temperature Control: Digital controller-cum-indicator

-

Inner Chamber: Stainless steel with externally clamped heaters

-

Outer Body: Mild steel with high quality glass wool insulation

-

Vacuum System: Vacuum gauge and vacuum cock mounted on right side

-

Indicators: Dual lamps for power and heater status

-

Accessories: Stainless steel perforated tray

-

Pump: Oil-sealed vacuum pump, quiet operation, continuous-duty tested

- Vacuum Pump Flow Rate: 57L/min 2CFM

-

Vacuum Pump Power: 1/4 HP

- Vacuum Pump Voltage/Frequency: 230V~/50-60Hz

-

Pump Construction: Metal-cased mechanism with oil sight gauge & drain plug

-

Motor Mounting: Pump fully assembled on rectangular base plate

Product Description

The Water Absorption Test Apparatus (gravimetric), also known as Vacuum Oven VO-281 is engineered to deliver precise and reliable performance for water absorption testing as per IS:10810 Part 33 or IS 7098. Its stainless steel inner chamber ensures durability and contamination-free operation, while the mild steel exterior with high-grade glass wool insulation maintains optimal temperature stability.

Equipped with a digital temperature controller-cum-indicator, the apparatus offers accurate monitoring and efficient heat management. The vacuum system includes a high-quality vacuum gauge and vacuum cock for convenient control during test procedures.

A robust oil-sealed vacuum pump ensures quiet, vibration-free, and continuous-duty operation. The pump assembly features an oil level sight gauge and drain plug for easy maintenance, while the motor-driven design ensures stable output. An air pump providing 7–12 LPM flow supports the chamber’s pressure requirements for standardized testing.

Ideal for electrical, material testing, and quality assessment labs, this apparatus delivers dependable performance, precise control, and long-lasting operational reliability.

Sources: IS 10810 Part 33, IS 7098-1