Description

Technical Specifications

-

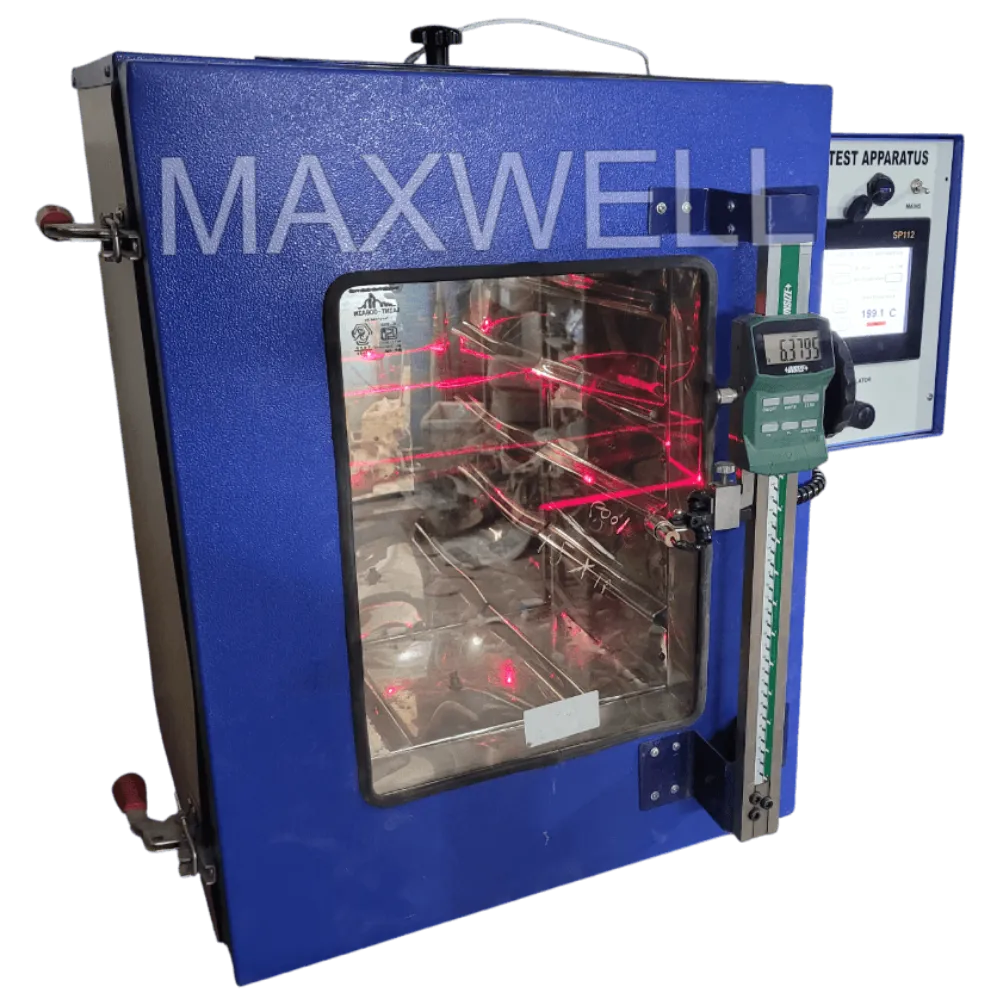

Model No.: HST-151-HMI

-

Test Standard: IS 10810 : 1984 (Part 30)

-

Application: Hot set and hot deformation test of cable insulation

-

Chamber Type: Double-walled cabinet

-

Inner Chamber Material: Stainless Steel SS-304

-

Outer Body Material: Mild Steel, powder-coated / painted

-

Inner chamber Size: Approx. 33 cm × 46 cm × 26 cm (W × H × D)

-

Temperature Range: Ambient to 200 °C

-

Temperature Accuracy: ±3 °C at sensor point

-

Temperature Controller: PID Controller with dual display (Set Value & Process Value) inbuilt in HMI

-

Air Changes: 8–20 air changes per hour

- Air Flow meter: Installed Honeywell/SMC or other equivalent brand air flow meter

-

Airflow Control: Rotameter with adjustable airflow

-

Air Compressor: Provided with the instrument at additional cost

-

Specimen Holding: Top-mounted grips for two specimens

-

Load Arrangement: Weight set up to 1 kg per specimen

-

Height Gauge Type: Laser fitted branded height gauge (In-size or Mitutoyo)

-

Observation: Full-view glass door

- HMI Display: Shows Timer for 15 mins and 5 mins, Air Flow (in LPM), Set Temperature, Actual Temperature, Hot Set Elongation, Permanent Set Elongation

- Data Logging: Saves data for more than 1000 records

-

Data Output: USB interface provided. Data can be downloaded in pdf and csv formats

- Weights Provided: 10 g (qty-2), 20 g (qty-2), 50 g (qty-2), 100 g (qty-2), 200 g (qty-1)

Product Overview

The Hot Set Test Apparatus HST-151-HMI is a precision test system designed to evaluate the elongation, deformation, and permanent set of cable insulation and sheathing materials at elevated temperatures. The apparatus conforms to IS 10810 : 1984 Part 30 and meets the hot set test requirements specified in IS 7098.

The unit consists of a double-walled, temperature-controlled oven that ensures uniform heating and stable test conditions. The stainless steel inner chamber provides excellent corrosion resistance and long service life.

Temperature & Airflow Control

The oven is fitted with a PID temperature controller in HMI Display offering dual digital display for both set value and actual process temperature. The system is capable of maintaining the required 200 °C ± 3 °C test temperature with high stability.

Controlled airflow is achieved through a bottom air inlet, ensuring air flows evenly across the surface of the test specimens before exiting near the top of the chamber. The airflow rate is monitored and regulated using a rotameter, providing consistent test conditions as required by the standard.

Specimen Mounting & Load System

Two specimens can be tested simultaneously using top-mounted hanging grips. Each specimen is subjected to a controlled load using calibrated weights up to 1 kg, allowing accurate evaluation of elongation under thermal stress. The full-view glass door enables continuous observation of specimen behavior during the test.

Features & Benefits

-

Conforms to IS 10810 Part 30 hot set testing requirements

-

Uniform temperature distribution with PID control

-

Stainless steel test chamber for durability

-

Controlled airflow for repeatable results

-

Dual specimen testing capability

-

Easy observation through full-view glass door

-

Suitable for routine QC and type testing

Applications

-

Hot set and deformation testing of power and control cables

-

Cable insulation and sheath material evaluation

-

Quality control laboratories

-

Cable manufacturing and R&D facilities

-

Certification and compliance testing labs