Description

Specifications

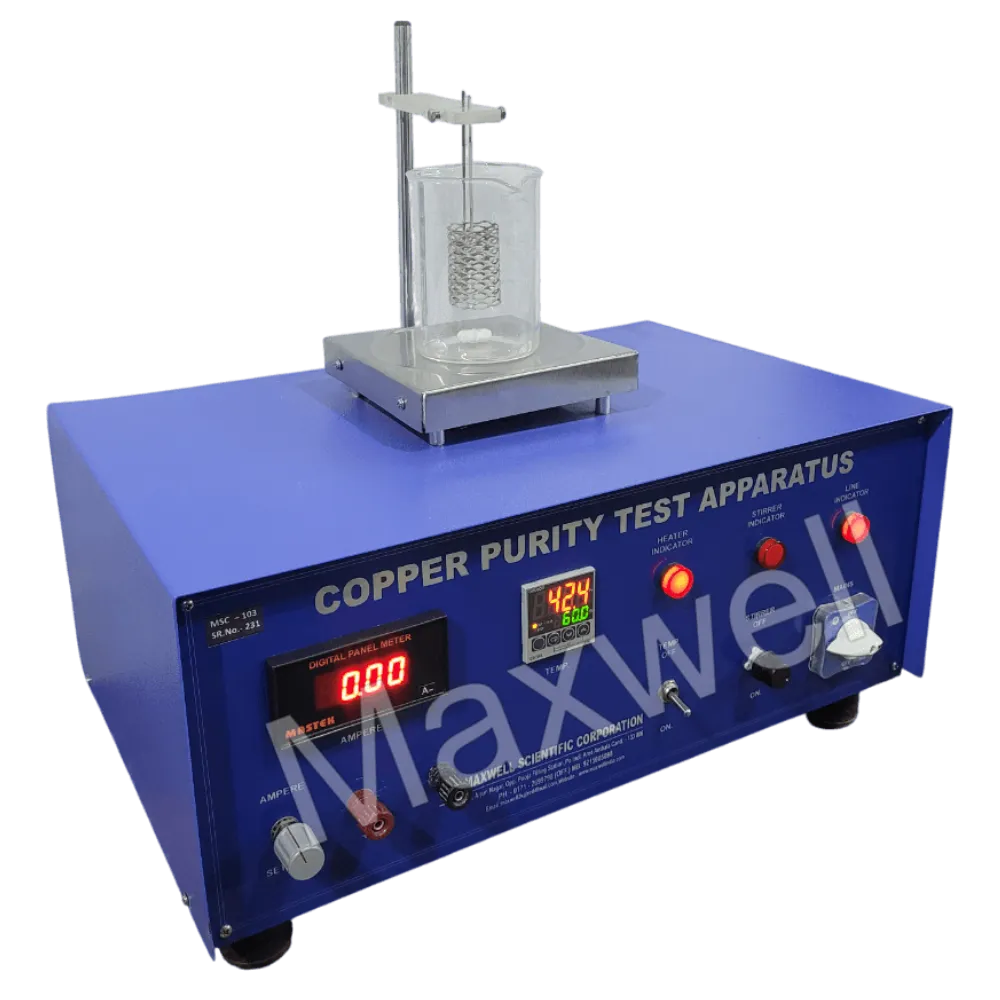

- Model: CPT-103

-

Application: Copper purity testing for cable, wire & conductor industry

-

Testing Standard: IS:191 (Pt-V & VI) 1980, IS:440-1964

-

Purity Measurement Range: Up to 99.9% (Electrolytic method)

-

Main Unit Indicators: Digital ampere meter & temperature

-

Controls: Multi-turn current regulator, ON/OFF switch, mains indicator

-

Magnetic Stirrer:

• DC motor with speed regulator

• Hot plate with energy regulator

• Stainless steel body with heat-resistant coating

• Load capacity: Generally 200 W, 220 V AC (depending on the requirement) -

Electrodes: Platinum–Iridium cathode and anode

-

Chemicals required:

• Sulphuric acid – 500 ml

• Nitric acid – 500 ml -

Included Glassware: Beaker, round bottom flask

-

Construction: Powder-coated main unit; stainless steel stirrer enclosure

-

Overall Dimensions (Main Unit): 5” × 12” × 15”

Product Description

The Copper Purity Test Apparatus is a complete analytical setup designed to determine the purity of Electrolytic Tough Pitch (ETP) copper with accuracy up to 99.9%. Engineered for cable, conductor, and electrical manufacturing industries, this apparatus follows IS:191 (Part V & VI) 1980 and IS:440-1964 standards, ensuring reliable and repeatable electrolytic purity testing.

Working Principle

The apparatus operates on an electrolytic deposition method where the copper sample is dissolved in a sulphuric acid–nitric acid solution. Copper is then deposited electrolytically on the platinum-iridium electrodes.

For copper purity below 99.5%, impurities are removed using ferric hydroxide before electro-deposition, ensuring highly accurate purity results.

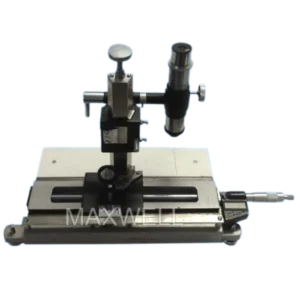

Main Unit Features

The main control unit includes digital ampere and volt indicators, a multi-turn current regulator for precise current setting, and a durable powder-coated body. It provides stable, controlled current essential for accurate copper deposition.

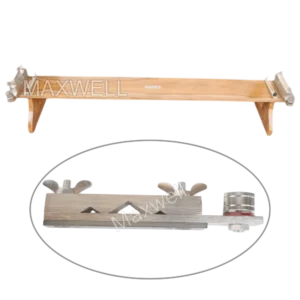

Magnetic Stirrer with Hot Plate

The stainless steel magnetic stirrer houses a DC motor for uniform mixing and a hot plate to maintain ideal temperature conditions. Adjustable motor speed and controlled heating allow optimized chemical reaction and uniform deposition.

High-Quality Electrodes

The platinum-iridium cathode and anode are manufactured to meet IS specifications, ensuring long service life, consistent results, and superior electro-chemical stability.

Applications

-

ETP copper purity testing

-

Cable and conductor manufacturing

-

Quality control laboratories

-

Electrical material inspection

-

Research & development on copper alloys