Understanding IS 1293: The Ultimate Guide to Plug & Socket Testing in the Laboratory

In an era where electrical safety is non-negotiable, ensuring that everyday components like plugs and sockets comply with rigorous standards is critically important. In India, this responsibility is governed by IS 1293 — the Indian Standard for plugs and socket outlets — with specific requirements that underpin electrical safety, performance, and reliability.

In this blog, we will take you on a deep dive into the IS 1293 plug and socket lab, covering everything from the standard’s background to detailed laboratory testing procedures, equipment requirements, performance benchmarks, and why these tests matter for manufacturers, regulators, and end users.

Table of Contents

- Introduction

- What Is IS 1293?

- Scope of IS 1293 Plugs and Sockets

- Why IS 1293 Matters

- Structure of an IS 1293 Testing Lab

- Types of Tests in IS 1293 Laboratories

- Equipment and Instrumentation Required

- Step-by-Step Testing Procedures

- Calibration and Quality Control

- Test Reporting and Documentation

- Implications for Manufacturers and BIS Certification

- Challenges in Testing

- Conclusion

1. Introduction

Electrical plugs and sockets are ubiquitous — present in every home, office, and industrial environment. But despite their common appearance, these components must be engineered and tested to withstand a variety of electrical, thermal, and mechanical stresses without compromising safety.

The IS 1293 standard, maintained by the Bureau of Indian Standards (BIS), defines comprehensive specifications and tests that determine whether a plug or socket can be certified for use in India. In this blog, we focus on the laboratory and testing aspects of IS 1293 — the backbone that ensures every certified product is safe and compliant.

2. What Is IS 1293?

IS 1293 is the Indian Standard titled “Plugs and Socket-Outlets for Household and Similar Purposes of Rated Voltage up to and Including 250 V and Rated Current up to and Including 16 A.” It was first issued in 2005 and later revised as IS 1293:2019 to update safety, dimensional, and performance requirements.

IS 1293 covers:

- Design and construction requirements

- Material and insulation specifications

- Mechanical and electrical performance criteria

- Safety tests under both normal and fault conditions

The standard applies to all plugs and socket-outlets intended for electrical household and similar purposes, such as powering appliances, lighting devices, tools, and other electrical equipment.

3. Scope of IS 1293 Plugs and Sockets

The standard covers:

- Rated Voltages: Up to 250 V

- Rated Currents: Up to 16 A

- Applications: Residential, commercial, and light industrial environments

It applies to the physical plugs and socket outlets that make up the connection interface between electrical wiring and equipment. Whether it’s a simple 6 A plug or a more robust 16 A socket, if it’s designed for use in India’s electrical system, it must conform to IS 1293.

Key Elements Defined in the Standard

The standard defines:

- Plugs: Devices with pins that insert into sockets

- Socket-outlets: Female connectors receiving plugs

- Rated Current and Voltage Conditions

- Safety features such as shutters, insulation, and earthing provisions Bureau of Indian Standards

4. Why IS 1293 Matters

Plugs and sockets may seem simple, but they are integral to personal and property safety. Non-compliant accessories can lead to serious hazards, including:

- Electric shocks

- Short circuits

- Fire risk due to overheating

- Equipment failure

With the Quality Control Order (QCO) in India, IS 1293 compliance and BIS certification (with the ISI mark) is mandatory for manufacturers before products are sold or marketed. These regulations are designed to ensure that every plug and socket on the market is safe for consumer use.

5. Structure of an IS 1293 Testing Lab

A compliant IS 1293 laboratory must be:

a) Fully Equipped

The lab should be outfitted with precision instruments and test fixtures capable of executing all required mechanical, electrical, and environmental tests.

b) Staffed with Qualified Personnel

Experienced technicians and engineers must perform tests, interpret results, and maintain test records.

c) Accredited and Calibrated

Equipment calibration and periodic quality checks are necessary to maintain accuracy and compliance. Bureau of Indian Standards

Basic Functional Areas in the Lab

- Mechanical Test Area – For insertion/withdrawal force, impact, and durability

- Electrical Test Area – For insulation resistance, dielectric strength, temperature rise

- Environmental Test Area – For humidity, heat, and ageing conditions

- Documentation Zone – For test reports, calibration records, and compliance certificates

6. Types of Tests Conducted in an IS 1293 Plug & Socket Testing Laboratory

IS 1293 specifies a comprehensive list of tests to verify the safety, durability, electrical integrity, and mechanical strength of plugs and socket outlets. These tests are mandatory for BIS certification and ensure that every plug/socket can withstand real-world usage without causing hazards like fire, shock, or overheating.

The tests fall into the following categories:

6.1 Dimensional and Construction Tests

These tests confirm that the shape, pin dimensions, spacing, and structural design comply with IS 1293 so that all plugs and sockets are interoperable.

Includes:

- Pin diameter, length, and spacing check

- Socket contact alignment

- Earthing pin dimensions

- Shutter mechanism inspection

- Material and insulation thickness check

6.2 Mechanical Tests

These tests evaluate the mechanical durability and robustness of plugs and sockets under repeated use and physical stress.

Includes:

- Insertion & withdrawal force test

- Endurance (plugging/unplugging cycles)

- Impact test

- Flexing test

- Pull-out / strain relief test

6.3 Electrical Tests

These are the most critical tests, ensuring safe operation under rated electrical load.

Includes:

- Insulation resistance

- Dielectric (high voltage) withstand

- Temperature rise test

- Breaking capacity

- Earth continuity test

- Contact resistance test

6.4 Environmental & Ageing Tests

These simulate long-term usage conditions such as moisture, heat, and ageing.

Includes:

- Heat resistance

- Ageing in oven

- Humidity test

- Glow wire/needle flame tests (fire resistance)

6.5 Safety Protection Tests

These ensure user protection from shock, fire, and mechanical hazards.

Includes:

- Protection against accidental contact

- Creepage & clearance measurement

- Verification of earthing reliability

- Shutter safety test

7. Instruments Required for IS 1293 Testing (With Detailed Descriptions)

Below is a complete list of instruments typically required in an IS 1293 laboratory, along with:

✔ What the instrument does

✔ Where it is used in the standard

✔ Which tests it performs

7.1 Vernier Calipers / Digital Calipers

Purpose

Measures pin diameter, slot width, pin length, and mechanical dimensions.

Used For

- Dimensional checks

- Construction verification

Tests It Performs

- Pin diameter measurement

- Socket aperture measurement

- Earthing pin length check

- Clearance dimensions

7.2 Go/No-Go Gauges (Pin & Socket Gauges)

Purpose

Fixed limit gauges that check whether dimensions meet standard tolerances.

Used For

Ensures plug pins and socket openings are neither too loose nor too tight.

Tests It Performs

- Pin tolerance verification

- Socket aperture acceptance

7.3 Force Gauge / Push-Pull Gauge

Purpose

Measures insertion and withdrawal force in Newtons.

Used For

Mechanical endurance and usability tests.

Tests It Performs

- Insertion force test

- Withdrawal force test

- Strain relief test

7.4 Socket Endurance Test Bench (Motorized)

Purpose

Automatically performs thousands of plug-in/plug-out cycles to simulate long-term use.

Used For

Mechanical endurance testing.

Tests It Performs

- Endurance (mechanical operating life)

- Wear & tear evaluation

- Contact spring fatigue test

7.5 Impact Test Device (Spring Hammer / Pendulum Hammer)

Purpose

Applies a controlled mechanical shock.

Used For

Mechanical strength and drop testing.

Tests It Performs

- Impact resistance test

- Cover plate strength

- Body crack resistance

7.6 Torque Screwdriver

Purpose

Measures tightening torque for terminals and screws.

Used For

Terminal screw tightening evaluation.

Tests It Performs

- Terminal torque test

- Mechanical anchoring strength test

7.7 High Voltage Breakdown Tester (Hipot Tester)

Purpose

Applies a high voltage (e.g., 2 kV – 4 kV) across insulation to test dielectric strength.

Used For

Electrical safety verification.

Tests It Performs

- Dielectric withstand test

- Insulation breakdown test

7.8 Insulation Resistance Tester (IR Meter / Megohmmeter)

Purpose

Measures insulation resistance (typically at 500 V or 1000 V DC).

Used For

Electrical insulation quality.

Tests It Performs

- Insulation resistance test

- Verification of moisture damage

7.9 Temperature Rise Test Setup

Includes:

- Heating oven

- Thermocouples

- Temperature sensors

- Data logger

- Electrical load bank

Purpose

Measures temperature rise inside pins, terminals, and contacts under rated load.

Used For

Thermal endurance and electrical safety.

Tests It Performs

- Temperature rise at rated current

- Overheating resistance

7.10 Load Bank / Resistive Load Setup

Purpose

Applies controlled electrical load (6 A, 10 A, 16 A).

Used For

Electrical performance tests.

Tests It Performs

- Temperature rise

- Breaking capacity

- Normal operation test

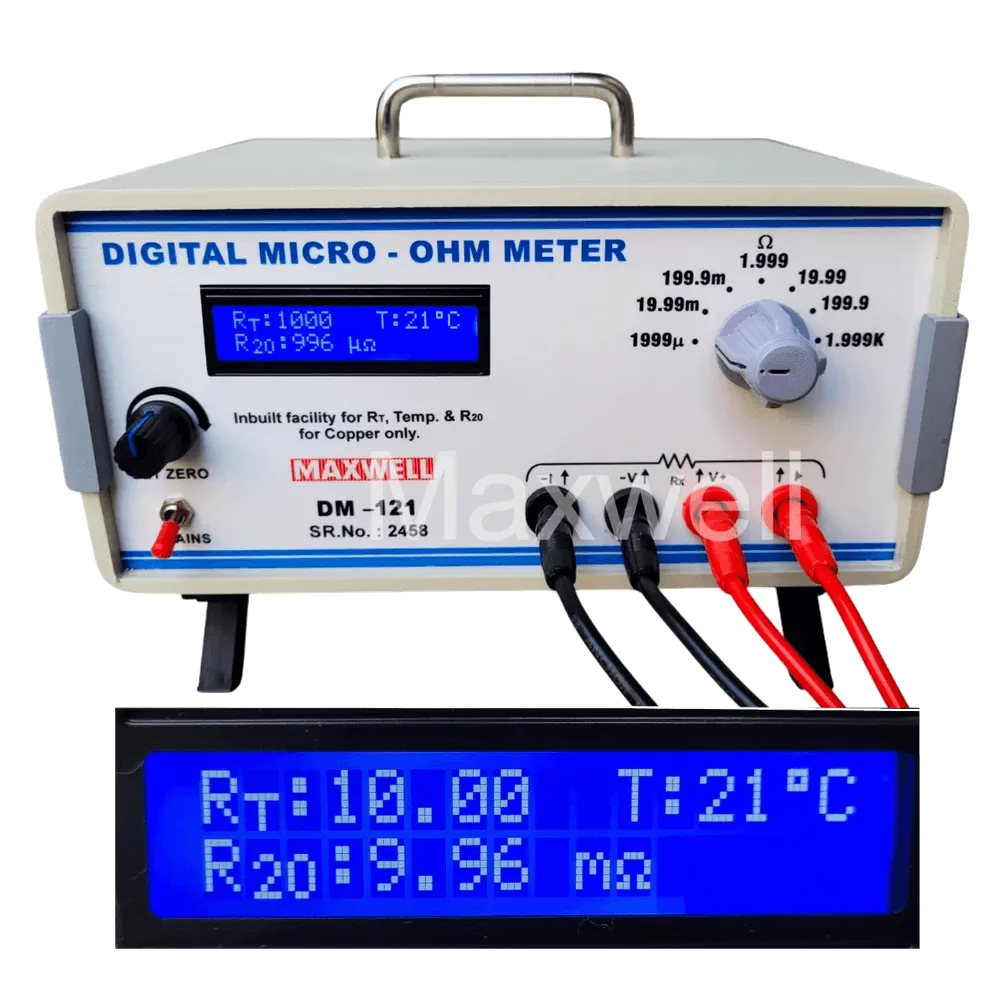

7.11 Continuity Tester / Micro-Ohm Meter

Purpose

Tests earth continuity and contact resistance.

Used For

Safety and grounding performance.

Tests It Performs

- Earth continuity test

- Contact resistance measurement

7.12 Humidity Chamber

Purpose

Simulates high-humidity environments (e.g., 95% RH at 40°C).

Used For

Environmental ageing tests.

Tests It Performs

- Humidity test

- Moisture effect on insulation

7.13 Ageing Oven / Hot Air Oven

Purpose

Accelerates ageing of plastic parts and insulation.

Used For

Heat resistance tests.

Tests It Performs

- Ageing test

- Heat deformation test

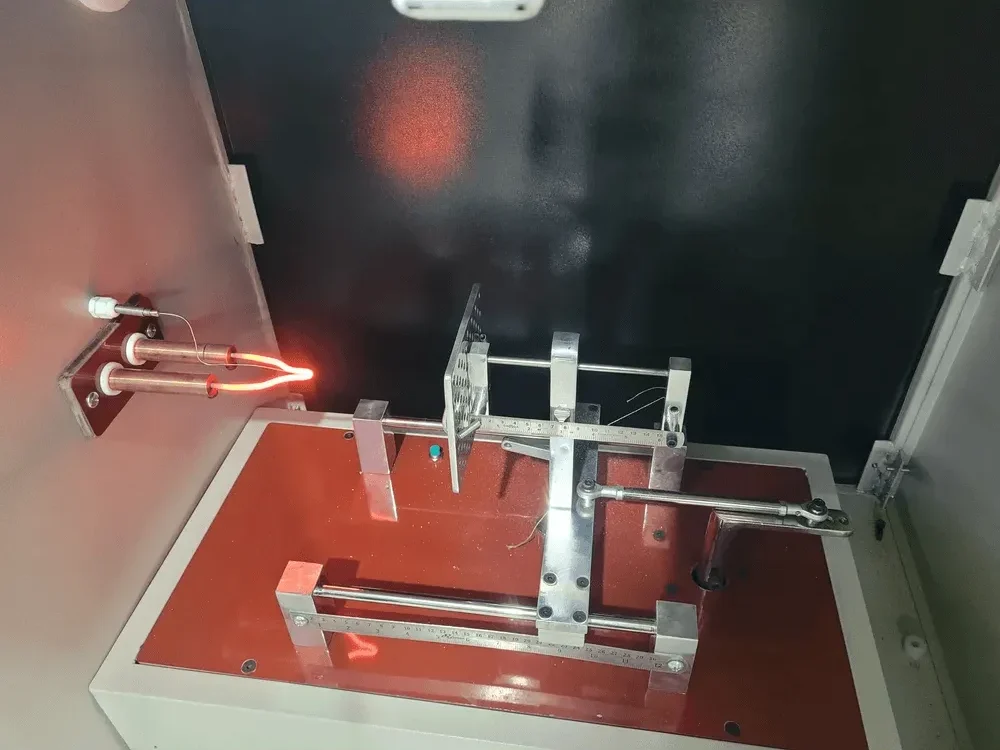

7.14 Needle Flame / Glow Wire Tester

Purpose

Tests fire resistance of insulating material.

Used For

Safety and flammability evaluation.

Tests It Performs

- Glow wire test (IEC 60695)

- Needle flame test

7.15 Creepage & Clearance Measurement Tools

Purpose

Measures insulation distances.

Used For

Safety compliance.

Tests It Performs

- Creepage distance check

- Clearance distance check

Here is the complete video of all the instruments required in IS 1293 Lab:

8. Step-by-Step Testing Procedures (Fully Detailed)

Below is a complete explanation of how each test is performed, with steps, conditions, and acceptance criteria.

8.1 Dimensional Test Procedure

Instruments Used

- Vernier caliper

- Go/No-Go gauges

Steps

- Clean the plug and socket surface.

- Measure pin diameter, length, and spacing using calipers.

- Check socket holes with Go/No-Go gauges.

- Compare all values with IS 1293 tolerances.

- Document deviations.

Pass Criteria

All dimensions must fall within declared tolerances.

8.2 Insertion and Withdrawal Force Test

Instrument

Force Gauge

Steps

- Secure the socket in a fixture.

- Attach plug to force gauge.

- Insert plug while recording force.

- Withdraw plug and note withdrawal force.

- Repeat 10–20 cycles.

Pass Criteria

Force must be within IS 1293 limits.

8.3 Mechanical Endurance Test

Instrument

Motorized endurance test bench

Steps

- Mount socket on endurance machine.

- Set number of cycles (e.g., 10,000).

- Insert/remove plug automatically.

- Monitor temperature & force variations.

- Inspect plug and socket for cracks or wear.

Pass Criteria

No excessive wear, deformation, or failure.

8.4 Dielectric Strength / High Voltage Test

Instrument

Hipot tester

Steps

- Apply specified AC voltage (e.g., 2000–4000 V).

- Connect terminals and insulation surfaces.

- Increase voltage gradually.

- Hold for 1 minute.

- Observe leakage current and breakdown.

Pass Criteria

No breakdown, sparking, or excessive leakage.

8.5 Insulation Resistance Test

Instrument

IR Tester (Megohmmeter)

Steps

- Set IR tester to 500V or 1000V.

- Connect across insulation barriers.

- Measure resistance for 60 seconds.

- Record readings.

Pass Criteria

Resistance must be above minimum threshold (e.g., >5 MΩ).

8.6 Temperature Rise Test

Instruments

Load bank, thermocouples, data logger

Steps

- Connect sample to rated load (e.g., 6A or 16A).

- Attach thermocouples to terminals and pins.

- Run test for 1–2 hours.

- Record temperature rise every 5 minutes.

- Compare values with IS 1293 limit.

Pass Criteria

Temperature rise should not exceed allowed °C limits.

8.7 Earthing Continuity Test

Instrument

Micro-ohm meter or continuity tester

Steps

- Connect earth pin to fixed point.

- Measure resistance via continuity meter.

- Confirm resistance value.

Pass Criteria

Earth resistance should be very low (typically <0.1 Ω).

8.8 Humidity Test

Instrument

Humidity chamber

Steps

- Place sample in chamber at 40°C and 95% RH.

- Leave for 48–96 hours.

- After removal, allow cooling.

- Perform IR and dielectric tests again.

Pass Criteria

No insulation breakdown after humidity exposure.

8.9 Ageing Test

Instrument

Hot air oven

Steps

- Place plastic parts in oven at defined temperature (e.g., 70°C).

- Age for 168 hours.

- Remove and inspect for cracks, deformation.

8.10 Fire Resistance Tests

Instrument

Glow wire / needle flame tester

Steps

- Heat glow wire to 650°C–850°C.

- Apply to sample surface.

- Observe flame duration and self-extinguishing behavior.

Pass Criteria

Material must extinguish within specified time limits.

9. Calibration and Quality Control

An IS 1293 lab isn’t just about performing tests — it’s about ensuring accuracy and reliability over time. This is done through:

a. Calibration Checks

All instruments must be calibrated against known standards at regular intervals. Calibration records are essential for traceability and audit purposes. Bureau of Indian Standards

b. Quality Control Protocols

Routine checks, statistical process control, and adherence to documented SOPs ensure quality is consistent across test cycles.

c. Record Keeping

Every test, instrument calibration, and result must be recorded meticulously. These records serve as evidence during audits and certification reviews.

10. Test Reporting and Documentation

Once tests are completed, results must be compiled into comprehensive test reports that include:

- Test parameters

- Equipment used

- Environmental conditions

- Results and observations

- Pass/Fail conclusion

These reports often form the basis of BIS certification and are shared with certification bodies and clients.

11. Implications for Manufacturers and BIS Certification

Manufacturers must perform these tests, either in their in-house labs or through BIS-recognized third-party laboratories, as part of the BIS certification process. Once a product passes all tests according to IS 1293, the manufacturer can apply for the ISI mark, which signifies compliance and safety.

Failure to comply means:

- Products cannot be legally sold in India

- Market access is restricted

- Brands may face consumer trust issues and legal penalties

Thus, a functioning IS 1293 test lab is a strategic asset for electrical product manufacturers.

12. Challenges in Testing

Even experienced labs face challenges:

Complex Test Setups

Some tests require precise control of multiple parameters simultaneously — electrical load, temperature, humidity — which demands advanced equipment and expertise.

Interpreting Failures

Determining whether a failure is due to the product or a testing anomaly takes skill and repeat verification.

Keeping Up with Updates

Standards like IS 1293 evolve over time — from 2005 to the 2019 revision — requiring labs to stay updated with the latest methods and thresholds. SIQ

13. Conclusion

The IS 1293 plug and socket lab is more than just a testing facility — it’s the guardian of electrical safety in everyday life. Whether you’re a manufacturer, engineer, or quality assurance professional, understanding how these laboratories operate is essential to producing products that are safe, reliable, and compliant with Indian regulations.

From dimensional checks to electrical endurance tests, each procedure contributes to the overall confidence consumers place in the humble plug and socket — a small device that plays a big role in our modern electrical ecosystem.

By investing in accurate testing and compliance with IS 1293, manufacturers not only secure a competitive advantage but also contribute to a safer electrical environment for everyone.