Glow Wire Test – A Comprehensive Guide for Safety, Standards, and Compliance

In modern electrical and electronic product manufacturing, safety is paramount. One of the key safety evaluations performed on products is the Glow Wire Test. This specialized flame retardancy and ignition hazard assessment helps verify that materials used in electrical equipment do not catch fire easily when exposed to heated metal parts or overheated components. With rapid growth in consumer electronics, lighting, home appliances, and industrial products, understanding the glow wire test has become critical for manufacturers, safety engineers, compliance specialists, and quality auditors.

This blog explains what glow wire test is, why it is important, which international and Indian standards it caters to, the components of the test, testing procedure, acceptance criteria, prominent manufacturers of test apparatus, and answers to commonly asked questions (FAQs).

What is a Glow Wire Test?

The Glow Wire Test is a controlled laboratory test that assesses the fire resistance, ignition, flame propagation, and glowing combustion characteristics of insulating materials and parts of electrical products under high temperature.

The test simulates a real-life scenario where an electrically heated component (e.g., a resistor, transformer winding, or overloaded conductor) reaches a high temperature and comes into contact with polymeric parts of a device.

Instead of using an open flame, a glow wire heated electrically to specific temperatures is pressed against the material and evaluated how it reacts.

The glow wire does not ignite open flames but mimics thermal stress caused by internal faults or localized overheating.

Why Glow Wire Test is used?

The primary goal of the Glow Wire Test is to evaluate fire safety and reduce risk of fire hazards in electrical products:

1. Simulating Real-World Thermal Hazards

Products may experience overheating due to:

- Component failure

- Poor contacts

- Overcurrent

- Prolonged use

Glow Wire testing simulates these scenarios by applying a heated wire on the material and observing reactions such as ignition, flame spread, and burning duration.

2. Assessing Material Flammability

Many electrical products use thermoplastics or insulating materials. These must resist ignition when exposed to high temperatures from internal faults. Glow Wire testing checks whether materials will ignite or self-extinguish.

3. Ensuring Product Safety Compliance

This test is required by various national and international safety standards to certify products before they reach the market, especially for household appliances, lighting, and electrical connectors.

Glow Wire Test & Safety Standards

Glow Wire testing isn’t random — it’s defined by formal standards used by manufacturers and testing labs. These standards specify test methods, temperatures, durations, pass/fail criteria, and reporting requirements.

🇮🇳 Indian Standards for Glow Wire Test

In India, the Bureau of Indian Standards (BIS) has adopted or aligned with international standards to ensure safety compliance under the Indian Standards (IS) system.

Key Indian standards include:

1. IS 11000-2-1 /IEC 60695 Series

BIS has adopted many parts of IEC 60695 for glow wire testing in India. The Indian standard version generally mirrors IEC requirements with minor regional modifications.

2. IS 13252 / IS 15885

Product safety standards for IT equipment and household appliances reference glow wire requirements based on IEC norms.

3. IS 1293 – Plastic Materials for Electrical Use

Provides requirements for plastics used in electrical equipment like Plugs and Socket, including thermal and flammability properties.

4. Compulsory Registration Scheme (CRS)

Under the CRS by the Indian Electronics and Information Technology Goods (Requirement for Compulsory Registration) Order, products in several categories must be tested per Indian/IEC standards, including glow wire tests, before registration and sale.

🌍 International Standards (IEC & others)

Internationally, Glow Wire testing is standardized primarily by the IEC 60695-2 series:

| Standard | What It Covers |

|---|---|

| IEC 60695-2-10 | Glow-wire apparatus and common test procedure – general test setup and test conditions. |

| IEC 60695-2-11 | Glow Wire Flammability Test for End Products (GWEPT). |

| IEC 60695-2-12 | Glow Wire Flammability Index (GWFI) for materials. |

| IEC 60695-2-13 | Glow Wire Ignition Temperature (GWIT) for materials. |

These are often referenced in product safety standards such as:

IEC 60335 (Household appliances), IEC 60598 (Luminaires), IEC 60884-1 (Plugs & sockets), IEC 60950 (IT equipment), and many more.

Other Standards Referencing Glow Wire Test

The glow wire test is also associated with:

- UL 746A (USA) — for plastics and components.

- BS EN 60695-2 — British/European equivalents.

- ASTM D6194-03 — Fire hazard testing method.

- IEC 829

- DIN695

- VDE0471

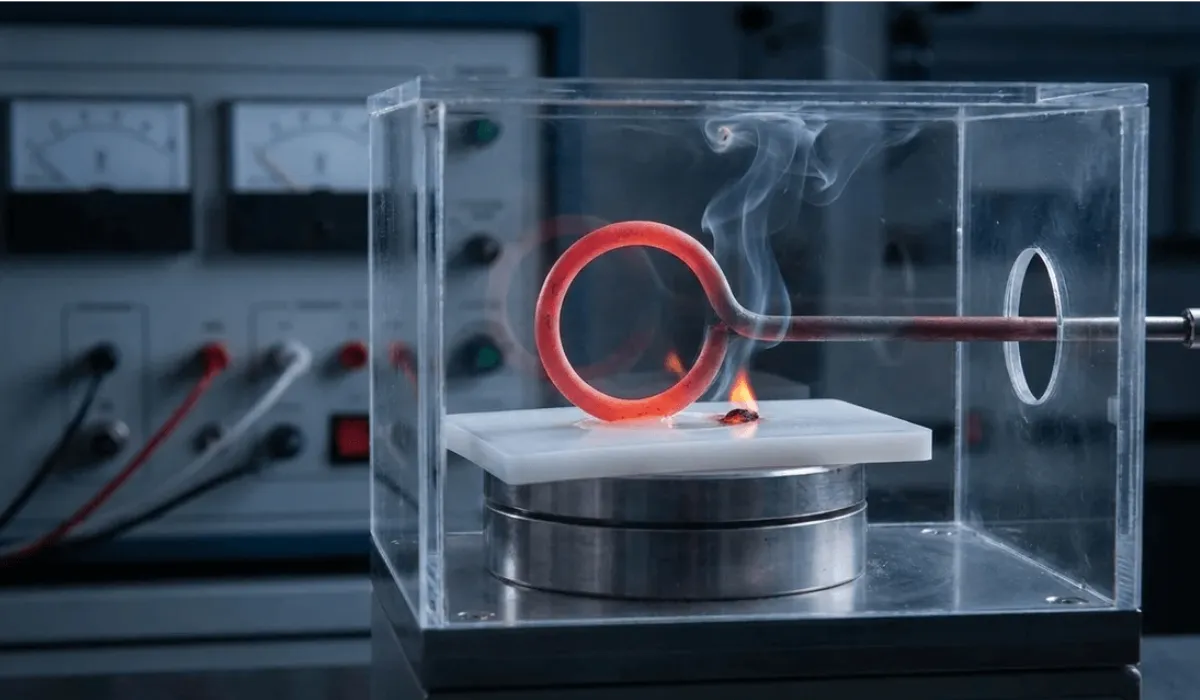

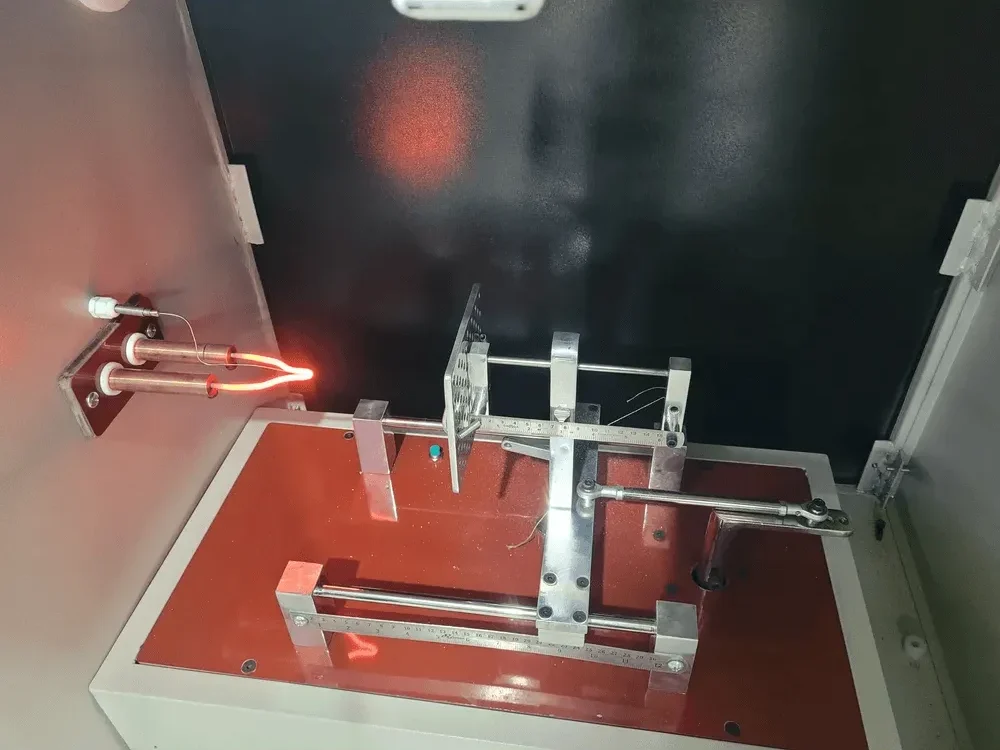

Components of a Glow Wire Test Setup

A typical glow wire test setup consists of essential components designed to simulate fire hazards in a controlled and repeatable manner:

1. Glow Wire

A nickel-chromium heating wire that gets electrically heated to specified temperatures (commonly up to ~960°C) to simulate a glowing hot surface.

2. Temperature Measurement System

A thermocouple (often a Type K chromel-alumel) embedded near the glow wire tip measures real temperature during the test.

3. Specimen Holder

Clamps or holders to position test specimens such as plastic parts, insulating materials, or assembled product sections.

4. Force & Contact Mechanism

A defined force (~1 N) pressing the hot wire against the test item, as specified in standards.

5. Data Logging & Timer

Precise timers record contact duration (typically 30 seconds) and flame time after removal.

6. Safety Chamber

Enclosed area that shields operators and allows observation of flames, ignition, and drips safely.

How the Glow Wire Test Works (Step-by-Step)

Let’s simplify the testing process:

- Preparation

Test specimens are conditioned and mounted per the standard. - Wire Heating

The glow wire is heated to a required temperature (e.g., 750°C, 850°C, 960°C) as specified for the particular product or material. - Application of Wire

The glowing wire is applied to the specimen with a defined force for a fixed period (usually 30 seconds). - Observation

After contact, the specimen is observed:- Does it ignite?

- How long does it burn?

- Are there flaming drips?

- Does it extinguish quickly?

- Evaluation

In general, materials and components pass glow wire tests if:- There is no ignition at prescribed temperatures.

- Any after-flame or glowing does not continue for longer than permitted limits.

- No flaming particles or drops that cause ignition of filter paper below.

- Structural integrity remains compliant.

- Different standards specify precise criteria. For example:

- GWFI (Glow Wire Flammability Index) required to be above a threshold (e.g., 650°C or 850°C) for materials used near live parts.

- GWIT (Glow Wire Ignition Temperature) must be above the specification for parts to avoid igniting under high-temperature exposure.

- Afterglow durations beyond set limits may fail the test.

Why Glow Wire Test Matters for Product Safety

✅ Helps prevent electrical fires in homes and industries

✅ Improves consumer confidence in products

✅ Ensures regulatory compliance for global markets

✅ Supports material selection for safer designs

✅ Reduces warranty costs linked to product failures

Common Industries and Products Needing Glow Wire Testing

Glow wire testing is widely required for:

- Household appliances (kettles, toasters, heaters)

- LED lighting fixtures and luminaires

- IT equipment and accessories

- Power supplies and adaptors

- Switches, sockets, and distribution boards

- Consumer electronics

- Industrial control panels

- Automotive electrical components (certain regions)

Manufacturers of Glow Wire Test Apparatus

Choosing a reliable test apparatus manufacturer is crucial for accurate and repeatable results. Some well-known and reputable manufacturers include:

- Maxwell India – Based in Ambala, Haryana. They manufacture Testing Instruments like Glow wire test apparatus. They also provide spares like thermocouple used in Glow Wire.

- Weiss Technik GmbH – Known for environmental and fire safety test systems and based out of Germany.

- Atlas Material Testing Solutions, USA – Thermal and fire test equipment.

- Thermal Hazard Technology – Specialized in fire hazard testing solutions.

- Tinius Olsen, Norway – Material testing equipment supplier.

- CSM Instruments – Fire safety testing products. CSM Instruments SA was acquired by Anton Paar in 2013.

- Labthink International, China – They make packaging and material testing systems, including flame testing.

- Chongqing Gold Mechanical & Electrical Equipment – Based in China

(Note: When selecting a manufacturer, check compliance, calibration support, local service availability, and standard certifications.)

🔍 FAQs (Frequently Asked Questions)

Here are more than 10 FAQs to address most questions about Glow Wire testing:

1. What exactly is a Glow Wire Test?

A standardized fire hazard test to assess how materials and products respond to a heated wire simulating thermal stress.

2. Why is the Glow Wire Test important?

It helps determine whether materials will ignite or sustain fire when exposed to overheating conditions typical of electrical faults.

3. Which products need Glow Wire Testing?

Household appliances, lighting fixtures, connectors, electronic equipment enclosures, switches, sockets, and more.

4. What standards govern Glow Wire Tests?

IS 1293, IEC 60695-2-10, -2-11, -2-12, -2-13, Indian IS 11000 series, UL 746A, ASTM D6194, and equivalents.

5. What is GWIT?

Glow Wire Ignition Temperature — the highest temperature at which a material does not ignite.

6. What is GWFI?

Glow Wire Flammability Index — a measure of material’s flammability when exposed to a glow wire.

7. What temperatures are used in testing?

Common test temperatures in Glow Wire Test include 550°C, 750°C, 850°C and up to 960°C depending on product and standard requirements.

8. How long is the glow wire applied?

Typically for 30 seconds, as per most standards.

9. Does Glow Wire Test apply to metals?

No — primarily used for plastic and insulating materials, not metals.

10. Is Glow Wire Test mandatory?

In many safety standards and regions, it’s mandatory for product certification and market entry.

11. Can Glow Wire Test detect ignition risks?

Yes — it’s specifically designed to simulate ignition from internal thermal faults.

12. Are there different test levels?

Yes — depending on material thickness, product type, and intended use, multiple temperatures and test conditions apply.

13. Who performs Glow Wire Testing?

Certified testing labs with appropriate apparatus and accredited procedures.

14. Can Glow Wire Test replace other flame tests?

It’s complementary — sometimes used with UL flame tests (e.g., UL 94), but not always interchangeable.

Conclusion

Glow Wire Testing is a cornerstone of electrical product safety, especially for devices with insulating materials that could ignite under abnormal heat. By following international and national standards such as IEC 60695-2 series and IS 11000, manufacturers ensure that products are safe, compliant, and fit for global markets.

Whether you’re a product developer, quality engineer, safety tester, or student, understanding Glow Wire testing helps you design and evaluate safer electrical products — protecting people and property from fire hazards.