DLRO vs DMM – What’s the Real Difference and Which One Do You Actually Need?

When it comes to electrical testing instruments, two tools are often confused with each other: DLRO (Digital Low Resistance Ohmmeter) and DMM (Digital Multimeter).

At first glance, both measure resistance. So many engineers, procurement teams, and even testing labs ask:

“Why can’t I just use a good DMM instead of buying a DLRO?”

We’ll go beyond basic definitions and cover:

- Technical differences

- Real-world applications

- Measurement accuracy factors

- Testing standards relevance

- Hidden limitations

- And some uncommon but critical FAQs

If you are involved in cable testing, switchgear manufacturing, transformer maintenance, or quality control, this guide will help you make the right choice.

What is a DLRO?

A DLRO (Digital Low Resistance Ohmmeter), also called a Micro Ohmmeter, is a precision instrument designed to measure very low resistance values, typically in the range of:

- 0.1 micro-ohm (µΩ)

- Up to a few ohms

It uses a high test current (10A, 50A, 100A or more) to measure extremely small resistances accurately.

Key Features of DLRO:

- 4-wire Kelvin measurement method

- High current injection. For example 0.1 Amp, 2 A, 10 A etc

- Micro-ohm resolution

- Designed for contact resistance measurement with very high current injection

- Used in heavy-duty industrial testing

DLROs are commonly used for:

- Busbar joints

- Switchgear contacts

- Transformer winding resistance

- Circuit breaker contact resistance

- Cable joint testing

- Earth bonding verification

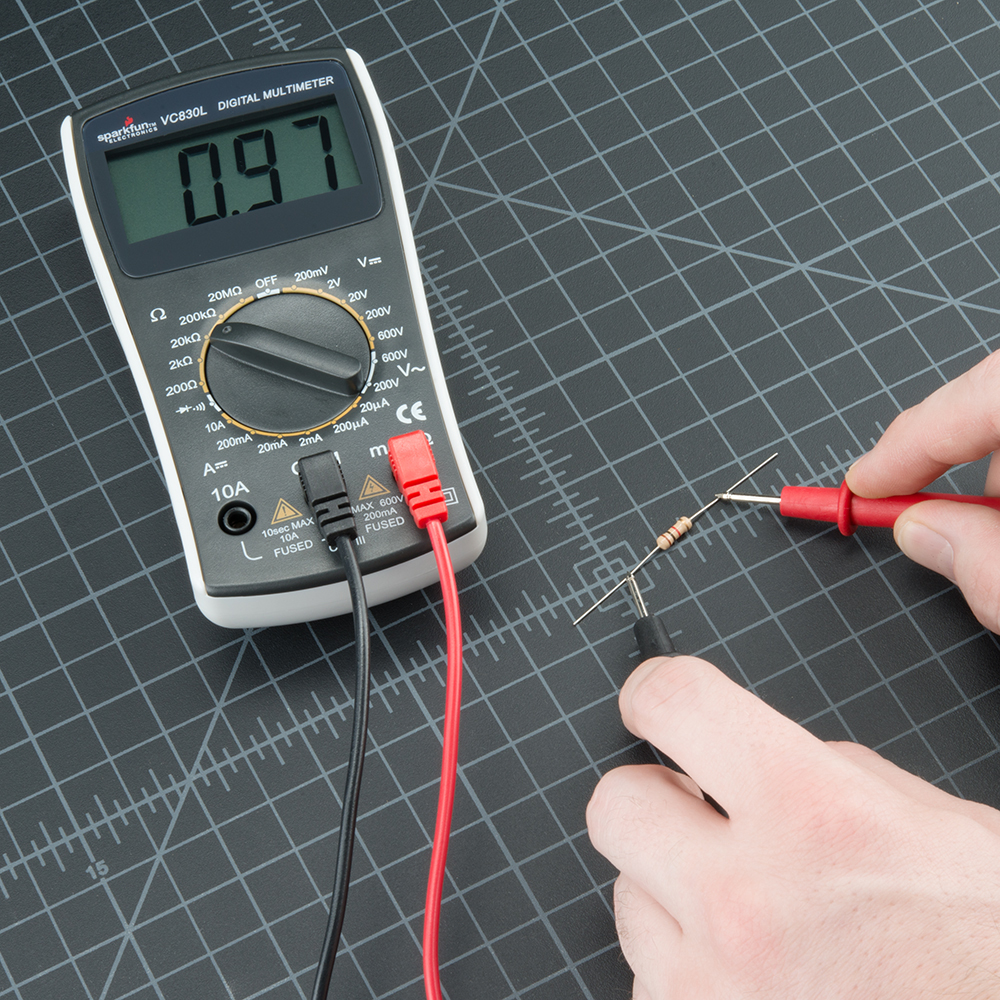

What is a DMM?

A DMM (Digital Multimeter) is a versatile instrument used to measure:

- Voltage (AC/DC)

- Current (AC/DC)

- Resistance

- Continuity

- Diode testing

- Sometimes frequency, capacitance, temperature

Resistance measurement in a DMM typically ranges from:

- 0.1 ohm to mega-ohms

But here’s the catch:

DMMs are not designed for ultra-low resistance measurement under high current conditions. As the readings are not accurate and precise due to many factors like it is a 2 wire measurement method and not 4 wire, the injection current is very small thus unstable readings etc

Core Difference: DLRO vs DMM

| Parameter | DLRO | DMM |

|---|---|---|

| Resistance Range | Micro-ohms to few ohms | Ohms to mega-ohms |

| Test Current | High (10A–100A+) | Very low (mA or µA) |

| Measurement Method | 4-wire Kelvin measurement method | Mostly 2-wire |

| Primary Use | Contact resistance | General purpose |

| Accuracy in µΩ | Very High | Poor |

| Industrial Suitability | Yes | Limited |

| Usage | Industrial Testing Labs for Cables, Transformer, Busbar etc. / NABL Labs / R&D Labs | Basic electronics testing / Multi purpose testing |

Why DMM Fails in Low Resistance Measurement

Let’s understand practically.

Suppose you want to measure the contact resistance of a busbar joint.

Actual resistance = 150 micro-ohms (0.00015 Ω)

A DMM:

- Uses low current

- Uses 2-wire method

- Includes lead resistance

- Includes probe contact resistance

Result? You may read:

- 0.3 Ω

- 0.2 Ω

- Fluctuating values

This is completely unreliable for industrial quality control.

How DLRO Solves This Problem

DLRO uses:

1️⃣ High Current Injection

Higher current creates measurable voltage drop across ultra-low resistance.

2️⃣ 4-Wire Kelvin Method

Separate:

- Current injection leads

- Voltage sensing leads

This eliminates:

- Lead resistance error

- Contact resistance error

3️⃣ Millivolt Precision Detection

Measures extremely small voltage drop accurately.

Real Industrial Example

If you manufacture:

- LT Panels

- HT Panels

- Switchgear

- Cable lugs

- Transformer assemblies

And your product requires compliance with standards like:

- IS

- IEC

- ASTM

Then DLRO becomes essential.

A DMM cannot validate contact resistance as per industrial standards.

1. Thermal EMF Effect

In micro-ohm measurement, even small temperature differences between two metals create thermal voltage (thermoelectric EMF).

DLROs often use:

- Current reversal technique

- Averaging method

DMMs do not compensate for this.

2. Load Simulation Capability

DLRO measures resistance under real load conditions.

DMM measures resistance under negligible current.

In high-current systems, contact behaves differently under load.

That difference matters.

3. Stability Over Time

DLRO readings are stable and repeatable.

DMM readings fluctuate in low resistance because:

- Probe pressure changes

- Oxidation

- Surface contamination

4. Cable Joint Quality Testing

In cable joint manufacturing, micro-ohm variation can indicate:

- Poor crimping

- Loose lug

- Surface oxidation

- Improper tightening torque

DMM cannot detect such subtle variations reliably.

When Can You Use a DMM Instead?

A DMM is perfectly suitable for:

- PCB troubleshooting

- Checking resistors

- Checking motor winding continuity

- Household wiring checks

- General electrical maintenance

If resistance is above 1 ohm, a good DMM is sufficient.

Cost Comparison

| Instrument | Approx Cost | Target User |

|---|---|---|

| Basic DMM | Low | Electricians |

| Industrial DMM | Medium | Service Engineers |

| DLRO 10A | Higher | QC Labs |

| DLRO 100A | Premium | Heavy Industry |

But remember:

A rejected panel or cable or transformer due to poor joint costs far more than a DLRO.

Accuracy Comparison

Let’s consider:

Resistance = 100 µΩ

DLRO error margin: ±0.5% or even better

DMM error margin: Practically unusable

The DMM simply does not have resolution capability for this range.

Safety Aspect

High current systems require:

- Proper clamping

- Thermal stability

- Heavy-duty leads

DLRO is built for this.

DMM probes are not designed for injecting 50A or 100A.

Frequently Asked Questions

FAQ 1: Can I improve DMM accuracy by shorting leads and subtracting resistance?

No.

Lead resistance compensation only removes static lead resistance.

It does not eliminate:

- Contact resistance variation

- Probe pressure variation

- Thermal EMF

- Surface oxidation effects

FAQ 2: Why does contact resistance change under high current?

Because:

- Microscopic contact points heat up

- Surface films break

- Metal deformation occurs

Only a DLRO reveals true operational resistance.

FAQ 3: Can DLRO detect loose bolts in switchgear?

Yes.

A small increase in micro-ohm value often indicates:

- Improper tightening torque

- Oxidized surface

- Improper busbar alignment

FAQ 4: Is 4-wire measurement always necessary?

For:

- Above 1 ohm → Not mandatory

- Below 1 ohm → Strongly recommended

- Below 10 milli-ohm → Essential

FAQ 5: Why do standards insist on high current resistance testing?

Because actual operating conditions involve high current flow.

Testing under unrealistic low current (like DMM) does not simulate real operation.

FAQ 6: Can DLRO damage delicate components?

Yes.

DLRO should never be used on:

- PCBs

- Small resistors

- Electronic circuits

It is meant for:

- Heavy metallic joints

FAQ 7: Can a high-end 6.5 digit bench DMM replace DLRO?

In laboratory conditions, maybe for milli-ohm range.

But:

- It still lacks high current injection

- It cannot simulate load

- It is not field rugged

Industrial DLRO remains superior for field use.

FAQ 8: Why does resistance increase over time in busbars?

Possible reasons:

- Oxidation

- Thermal cycling

- Mechanical vibration

- Improper torque

Regular DLRO testing helps predictive maintenance.

FAQ 9: What test current should I choose – 10A or 100A?

Depends on:

- Application

- Busbar size

- Industry standard

- Required test sensitivity

Higher current provides:

- Better resolution

- More realistic simulation

But it should be as per defined IS / IEC standards. As very high currents can also lead to increase in temperature of the conductor sample and change the resistance being measured.

FAQ 10: Can DLRO be used for earthing system testing?

Yes, for bonding resistance measurement.

But for soil resistivity measurement, an earth tester is used.

DLRO vs DMM – Decision Guide

Choose DMM if:

- You need multi-function testing

- Resistance > 1 ohm

- General troubleshooting

Choose DLRO if:

- You measure contact resistance

- You work in panel manufacturing

- You test transformer windings

- You need compliance documentation

- You require micro-ohm accuracy

Final Verdict

Both instruments are essential — but for very different purposes.

A DMM is a general physician.

A DLRO is a specialist surgeon for low resistance measurement.

If your industry depends on reliable joints, safe current flow, and compliance testing, a DLRO is not optional — it is necessary.