Description

Specification

- Chamber Type: Double Walled Cabinet

- Inner Chamber Material: Stainless Steel SS-304

- Inner chamber Size: Approx. 33 cm × 46 cm × 26 cm (W × H × D)

- Outer Chamber Material: Powder Coated Mild Steel

- Temperature Range: Room temperature to 200°C

- Temperature Accuracy: ±3°C at sensor point

- Temperature Least Count: 0.1°C

- Air flow rate: 8 to 20 changes per hour

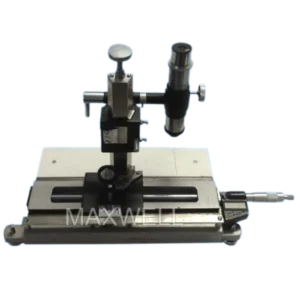

- Height Gauge Type: Laser fitted(optional)

- Standard: IEC 60811-507, IS 10810-30 (1984)

- Weights: 10 g (qty-2), 20 g (qty-2), 50 g (qty-2), 100 g (qty-2), 200 g (qty-1)

Apparatus Construction

-

Cabinet: Double-walled structure with a stainless steel inner chamber and a mild steel outer body, duly painted for durability.

-

Inner Chamber Dimensions: Approx. 33 cm × 46 cm × 26 cm (W × H × D)

-

Observation Door: Fitted with a full-view glass window to observe specimens during testing.

Performance & Controls

-

Temperature Range: Ambient to 200 ± 3°C at the sensor point.

-

Controller: PID controller with dual digital display for set and process values.

-

Air Circulation: Designed for 8–20 air changes per hour, ensuring uniform temperature distribution.

-

Air Inlet/Outlet: Air enters from the bottom, flows over the test pieces, and exits near the top for efficient circulation.

-

Air Flow Meter: Monitors and controls airflow rate.

-

Optional Accessory: Air Compressor & Laser height gauge (available on request).

Testing Features

-

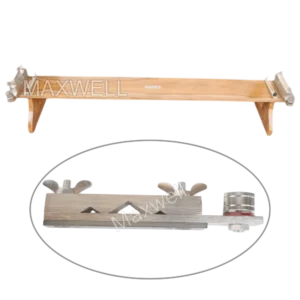

Grips: Provided at the top of the oven to hang up to two specimens conveniently.

-

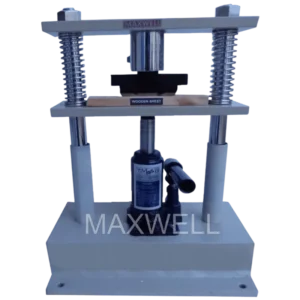

Weights: A complete set of calibrated weights (up to 1 kg) supplied with each unit for load application.

-

Elongation Measurement: Equipped with external non-contact distance measurement laser height gauge to read elongation directly without opening the chamber door, maintaining test conditions.

-

Sample Capacity: Up to four samples can be hung, but two are recommended to avoid contact between weights.

-

Timer: Built-in timer (up to 99 minutes) as per the latest IS amendment.

Key Benefits

-

Accurate elongation testing via laser height gauge

-

Dual-display PID temperature control

-

Safe, visible testing through glass window

-

Optional laser measurement for precision

-

Durable, industrial-grade construction