How to Test Conductivity of Copper and Aluminum: A Step-by-Step Guide

Electrical conductivity is one of the most critical parameters in evaluating the quality and performance of electrical cables and wires. Whether you are a cable manufacturer, testing laboratory, quality control engineer, or regulatory inspector, understanding how to test the conductivity of copper and aluminum conductors is essential to ensure compliance with international standards and reliable field performance.

In this detailed guide, we will explain what electrical conductivity is, why it matters, units of conductivity, conductivity formula, and most importantly, a step-by-step procedure to test conductivity of copper and aluminium conductors using practical methods commonly adopted in the industry.

This blog also includes real testing demonstrations through embedded videos to help you visually understand the process.

What Is Electrical Conductivity?

Electrical conductivity refers to a material’s ability to allow the flow of electric current. In simple terms, it tells us how easily electrons can move through a conductor when a voltage is applied.

The higher the conductivity, the lower the resistance offered by the material.

Definition of Conductivity

Electrical conductivity is the reciprocal of electrical resistivity.

Mathematically:

Conductivity (σ) = 1 / Resistivity (ρ)

Where:

- σ = Electrical conductivity

- ρ = Electrical resistivity or rho

Why Conductivity Testing of Cables and Wires Is Important

Conductivity testing is not just a laboratory exercise—it directly impacts safety, efficiency, and energy losses in electrical systems.

Key Reasons to Test Conductivity

- Verify purity of copper or aluminium

- Ensure compliance with IS, IEC, ASTM, BS standards

- Detect substandard or alloyed material

- Prevent excessive heating and power losses

- Confirm current-carrying capacity

- Quality control for incoming raw material and finished cables

A cable with lower-than-required conductivity will have higher resistance, leading to voltage drop, energy loss, and long-term reliability issues.

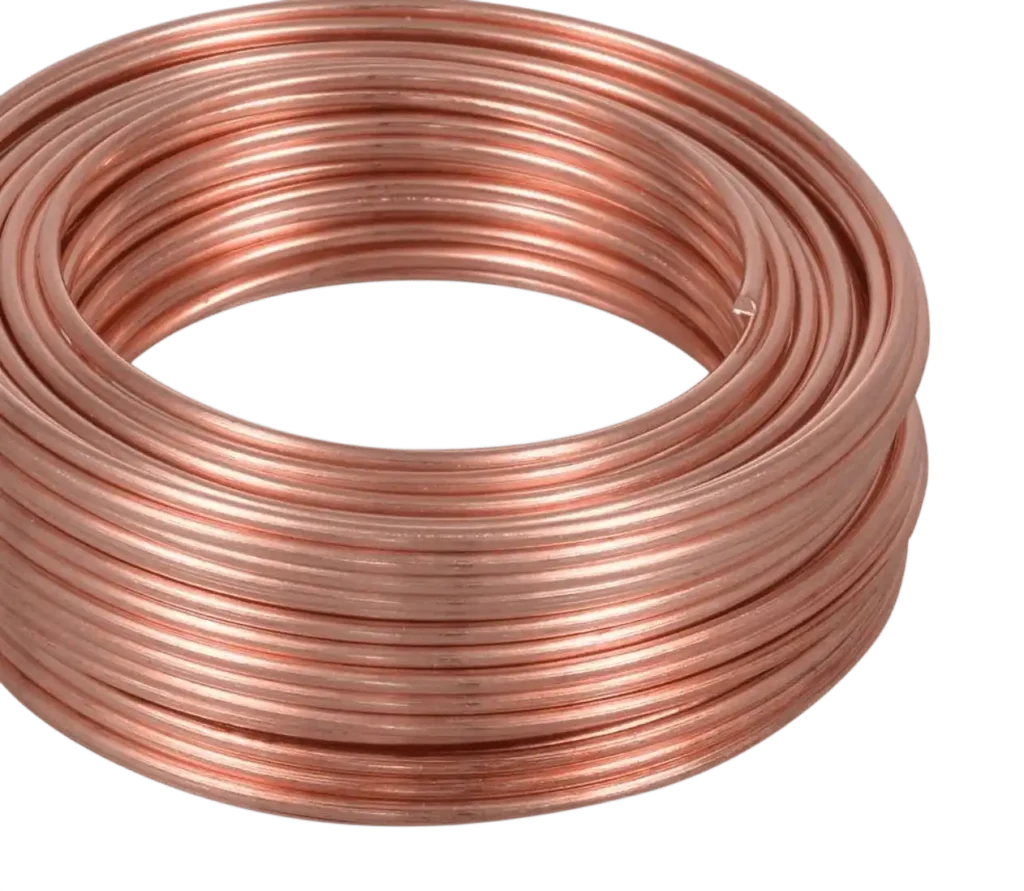

Conductivity of Copper

Copper is the most widely used electrical conductor due to its excellent electrical conductivity, mechanical strength, and corrosion resistance.

Copper Conductivity Values

- Standard reference: Annealed Copper

- Conductivity: 100% IACS

- Resistivity at 20°C: 1.724 µΩ·cm

- Conductivity: 58 MS/m (Mega Siemens per meter)

Copper Conductivity in Practice

High-purity electrolytic copper used in cables typically shows:

- 99.9% purity

- Conductivity close to 100–101% IACS

Even small impurities significantly reduce copper conductivity, which is why testing is critical.

Conductivity of Aluminium

Many people ask: Is aluminum conductive?

Yes—aluminium is conductive, but not as conductive as copper.

Conductivity of Aluminium

- Conductivity: ~61% IACS

- Resistivity at 20°C: 2.826 µΩ·cm

- Conductivity: ~35 MS/m

Why Aluminium Is Still Used

Despite lower conductivity, aluminium is widely used because:

- It is lighter than copper

- More cost-effective

- Suitable for overhead lines and large cross-sections

To compensate for lower conductivity, aluminium conductors are typically made thicker than copper.

Copper vs Aluminium Conductivity (Comparison Table)

| Property | Copper | Aluminium |

|---|---|---|

| Electrical Conductivity | ~100% IACS | ~59% IACS |

| Resistivity | Lower | Higher |

| Weight | Heavier | Lighter |

| Cost | Higher | Lower |

| Usage | Power, control, instrumentation cables | Power cables, overhead lines |

Conductivity Units Explained

Understanding conductivity units is essential while interpreting test results.

Common Units of Conductivity

- Siemens per meter (S/m) – SI unit

- Mega Siemens per meter (MS/m) – commonly used

- % IACS (International Annealed Copper Standard) – industry standard

What Is % IACS?

- 100% IACS = conductivity of annealed copper at 20°C

- Aluminium ≈ 61% IACS

- Copper alloys < 100% IACS

Conductivity Formula Used in Testing

In cable testing, conductivity is often derived from resistance measurement.

Resistance Formula

R = ρ × L / A

Where:

- R = Resistance (ohms)

- ρ = Resistivity

- L = Length of conductor

- A = Cross-sectional area

Once resistance is measured, conductivity can be calculated using standard tables or software built into a conductivity meter.

Methods for Conductivity Testing of Cables and Wires

There are two widely accepted methods:

1. Resistance Measurement Method (Most Common)

- Measure DC resistance of a known length

- Apply temperature correction

- Convert resistance to conductivity (% IACS)

2. Eddy Current Method

- Non-destructive

- Faster

- Common in rod and wire drawing industries

For finished cables and laboratory testing, the resistance measurement method is preferred due to its higher accuracy.

Instruments Used for Conductivity Testing

To test electrical conductivity accurately, the following instruments are commonly used:

- Micro Ohm Meter

- Kelvin Double Bridge

- Precision Conductivity Meter

- Temperature Sensor (RTD / Thermometer)

- Four-terminal (Kelvin) test leads

For low-resistance conductors, 4-wire Kelvin measurement is essential to eliminate lead resistance errors.

Step-by-Step Guide: How to Test Conductivity of Copper and Aluminum

Step 1: Sample Preparation

- Cut a clean conductor sample

- Ensure no oxidation or insulation residue

- Measure length accurately (usually 1 meter)

Step 2: Measure Cross-Sectional Area

- Use micrometer or calculate from diameter

- Accuracy here is critical

Step 3: Measure Temperature

- Conductivity is temperature-dependent

- Standard reference temperature: 20°C

Step 4: Measure DC Resistance

- Use a micro-ohm meter or Kelvin bridge

- Ensure stable connections

- Take multiple readings for accuracy

Step 5: Temperature Correction

- Apply correction factor to convert measured resistance to 20°C equivalent

Step 6: Calculate Conductivity

- Convert corrected resistance to conductivity

- Express results in % IACS or MS/m

Real Demonstration: Conductivity Testing Videos

To help you better understand the practical procedure, you can embed the following videos in your blog:

Video 1: Copper Conductivity Testing

This video demonstrates step-by-step conductivity testing of copper conductors using precision instruments.

Video 2: Aluminium Conductivity Testing

This video explains how aluminium conductor conductivity is measured and evaluated against standards.

These real-world demonstrations help bridge the gap between theory and practice.

Common Mistakes in Conductivity Testing

- Ignoring temperature correction

- Poor contact resistance

- Incorrect length measurement

- Oxidized conductor surface

- Using 2-wire measurement for low resistance

Avoiding these mistakes significantly improves test accuracy.

Standards for Conductivity Testing

Conductivity testing is governed by several international standards:

- IEC 60228

- IS 8130

- ASTM B193

- BS EN 60228

Always verify which standard applies to your application.

Applications of Conductivity Testing

- Cable manufacturing quality control

- Incoming raw material inspection

- Government and third-party testing labs

- BIS, RITES, and utility inspections

- Failure analysis and audits

Conclusion

Electrical conductivity testing of copper and aluminium cables is a fundamental quality assurance step that ensures safety, efficiency, and regulatory compliance. By understanding what conductivity is, units of conductivity, conductivity formula, and following a proper step-by-step testing procedure, manufacturers and laboratories can confidently assess conductor quality.

With the right conductivity meter, proper temperature correction, and adherence to standards, conductivity testing becomes a powerful tool to detect substandard materials and maintain trust in electrical systems.

If you are involved in cable testing, mastering conductivity measurement is not optional—it is essential.

Please contact us for more information +91-9215005098 or email: mona.maxwellindia@gmail.com