Grips for Tensile Testing Machines: Types, Applications & Complete Guide

In any tensile testing system, the load cell, extensometer, and machine frame often get the most attention. But in actual practice, the grips are the heart of a reliable tensile test. They determine whether your specimen stays firmly held throughout the test, whether the load is transferred accurately, and whether the final results—tensile strength, elongation, yield point—are valid.

Even the best universal testing machine (UTM) cannot deliver accurate results if the sample slips, breaks outside the gauge length, or gets damaged due to incorrect gripping. That is why choosing the right grip for the right material is essential.

This guide covers everything you need to know about tensile testing grips—their purpose, types, applications, selection criteria, and step-by-step testing guidance.

1. Why Grips Are Important in Tensile Testing

Although tensile testing seems simple—pull a material until it breaks—the challenge lies in how the material is held. Incorrect gripping leads to:

- Slippage of the sample

- Uneven load distribution

- Premature failure near the jaws

- Incorrect elongation readings

- Invalid stress–strain curve

Grips ensure:

- The specimen is held securely

- Load is transferred uniformly

- No additional stress concentrations are introduced

- No slippage occurs during high elongation

- The specimen breaks at the correct gauge length

Because every material behaves differently under tension, a single type of grip cannot work for all samples. Hence, manufacturers, labs, and QC teams must choose the correct grip per test standard (ASTM, ISO, IS, IEC, etc.).

2. How Grips Work – Basic Principle

A tensile testing grip has two main purposes:

- Hold the sample firmly without causing damage.

- Transfer tensile force from the machine to the sample consistently.

Most grips work using:

- Mechanical tightening

- Wedge/self-tightening action

- Pneumatic pressure

- Hydraulic clamping

- Special locking jaws

The choice depends on the shape, strength, thickness, and surface finish of the specimen.

3. Types of Grips for Tensile Testing Machines

This is the most important section—understanding which grip is used for which material/application.

We’ll cover:

- Wedge Grips

- Pneumatic Grips

- Mechanical Screw Grips

- Hydraulic Grips

- Vise (Vice) Grips

- Capstan Grips

- Compression / Shear Grips (special cases)

- Peel, Tear & Puncture Grips (special applications)

- Special Grips for Wire, Rope & Cable

- Custom and Application-Specific Grips

Let’s go through each type in detail.

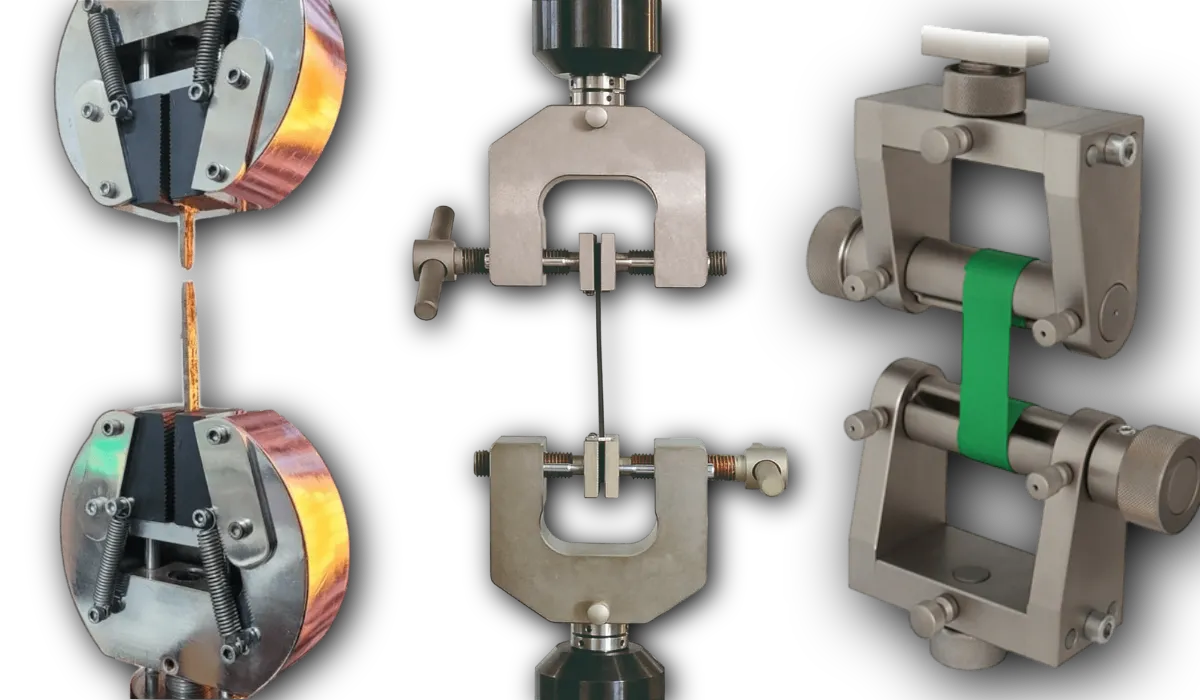

4. Wedge Grips (Self-Tightening Grips)

Wedge grips are the most common and versatile grips used worldwide.

How They Work

The jaws move inward as tensile load increases. The more load applied, the tighter they grip—ensuring self-tightening action.

Best For

- Metals (steel, copper, aluminum)

- Hard plastics

- Composite materials

- Specimens with minimal elongation

When to Use

Use wedge grips when:

- High load capacity is required (50 kN – 600 kN)

- The sample has a high modulus

- You want a secure hold without pneumatic/hydraulic systems

Advantages

- High gripping force

- Reliable for rigid materials

- Works with flat and round samples

Disadvantages

- May crush soft materials

- Not ideal for highly elastic specimens

5. Pneumatic Grips

How They Work

These grips use compressed air to apply uniform pressure on the specimen. Pressure can be adjusted precisely.

Best For

- Soft materials

- Rubber, elastomers

- Plastic films

- Paper, textiles

- Flexible packaging

- Medical tubing

When to Use

Use pneumatic grips when:

- Consistent clamping pressure is required

- Testing thin, delicate, or elastic materials

- Repetitive testing demands quick jaw operation

Advantages

- Uniform pressure on sample

- Avoids stress concentration

- No damage to the sample

- Very fast operation

Disadvantages

- Not suitable for very high loads

- Requires an air compressor

6. Mechanical Screw Grips

How They Work

The operator tightens the jaws manually using a screw mechanism.

Best For

- General-purpose tensile testing

- Plastics, rubber (low hardness)

- Soft metals

- Small components

When to Use

Ideal when:

- Budget is limited

- Lower frequency of testing

- Medium load capacity is needed

Advantages

- Affordable and simple

- Good for small labs and universities

Disadvantages

- Slower than pneumatic

- Clamping force depends on operator skill

7. Hydraulic Grips

How They Work

Hydraulic fluid generates very high clamping force—ideal for high-strength materials.

Best For

- Steel rods

- Steel plates

- Aerospace materials

- Composite laminates (high strength)

- High-capacity universal testing machines (UTMs)

When to Use

Use hydraulic grips when:

- Tensile load exceeds 300 kN

- Sample slippage is a concern

- You need perfect alignment with high force

Advantages

- Extremely high gripping force

- Very reliable for rigid materials

Disadvantages

- Expensive

- Requires hydraulic power unit

8. Vise (Vice) Grips

How They Work

Clamp the specimen like a conventional vice using a tightening screw.

Best For

- Rigid materials with rectangular cross-section

- Plastics

- Light metal samples

Advantages

- Cheap and simple

- Reliable for low-load testing

Disadvantages

- Not self-tightening

- Limited to small loads

9. Capstan Grips

How They Work

The specimen is wrapped around a rotating drum (capstan). This reduces slippage by distributing load over a larger surface.

Best For

- Yarn, textiles

- Ropes, threads

- Fiber bundles

- Cables

- Rubber strips

- Tapes

When to Use

Perfect for materials where:

- Grip-induced breaking is common

- Sample is flexible and elongated

Advantages

- Zero slippage

- Prevents premature breaks at gripping area

- Gentle on fragile samples

Disadvantages

- Not suitable for rigid materials

10. Peel, Tear & Puncture Grips

These grips are made for special tests.

Peel Grips (90° / 180° Peel Tests)

Best for:

- Adhesive tapes

- Laminated films

- Foils

- Sticker labels

Tear Grips

Used for:

- Rubber sheets

- Plastic films

- Paper

Puncture / Needle Grips

Used for:

- Medical needles

- Packaged materials

- Soft materials testing

11. Specialized Grips for Wire, Rope & Cable

Cables slip easily under tension. They require specially designed grips such as:

Wedge Wire Grips

For stranded copper/aluminum cables.

Self-Tightening V-Grips

For wires under 1 mm to 5 mm.

Capstan Rope Grips

For large-diameter ropes.

Crimp Grips

For terminals, lugs, and connectors.

Why These Are Needed

Normal grips damage or cut the cable, causing premature failure. Wire grips distribute force smoothly.

12. Compression & Shear Grips (Special Cases)

Though not purely “grips,” UTMs also use:

Compression Platens

For:

- Rubber blocks

- Foam

- Plastic components

Shear Fixtures

For:

- Adhesive tests

- Laminates

13. How to Select the Right Grip – Checklist

Choosing the correct grip ensures accurate and repeatable results. Follow this selection checklist:

1. Material Type

- Metal → Wedge/Hydraulic

- Plastic → Screw/Pneumatic

- Rubber → Pneumatic

- Wire/Rope → Capstan/Wire Grip

- Film/Paper → Pneumatic

2. Sample Thickness

Thin → Pneumatic

Thick → Wedge

3. Expected Elongation

High elongation → Pneumatic or Capstan

Low elongation → Wedge or Hydraulic

4. Load Capacity

Low (up to 1 kN) → Screw/Pneumatic

Medium (1–50 kN) → Pneumatic/Wedge

High (50–600 kN) → Hydraulic/Wedge

5. Surface Finish

Smooth → Pneumatic with rubber jaws

Hard → Wedge with serrated jaws

6. Testing Standards (ASTM, ISO, IS)

Always match grips to the relevant standard:

- ASTM D412 – Rubber tensile test → Pneumatic grips

- ASTM D638 – Plastic tensile → Wedge or Screw grips

- IS 1608 – Metal tensile → Wedge/Hydraulic grips

- ASTM D882 – Film tensile → Pneumatic grips

14. Step-by-Step Tensile Testing Procedure (With Correct Gripping)

Step 1: Choose the Correct Grip

Select grip based on material and standard.

Step 2: Install the Grip on the Machine

Ensure proper alignment to avoid bending load.

Step 3: Insert the Specimen

Make sure the sample is perfectly vertical.

Step 4: Apply Initial Clamping Pressure

- Pneumatic → Set air pressure

- Wedge → Hand tighten

- Hydraulic → Activate hydraulic pressure

Step 5: Zero the Machine & Extensometer

Step 6: Start the Test

Machine pulls sample at defined speed.

Step 7: Monitor Slippage

If slippage occurs:

- Increase pressure

- Change jaws

- Use correct grip type

Step 8: Note Break Location

Valid break → Within gauge length

Invalid break → Near jaws → Change grip

Step 9: Save Results

Stress-strain graph, tensile strength, yield point, elongation, modulus.

15. Common Gripping Problems & Solutions

| Problem | Reason | Solution |

|---|---|---|

| Slippage | Wrong grip | Use pneumatic/capstan |

| Sample damaging | Serrated jaws | Switch to rubber-coated jaws |

| Premature break | Stress at grips | Better alignment, correct grip |

| Uneven holding | Wrong jaw shape | Use jaws matching sample shape |

| Operator-dependent results | Screw grips | Move to pneumatic grips |

16. Comparison Table – Which Grip for Which Material

| Material | Recommended Grip | Reason |

|---|---|---|

| Metals | Wedge / Hydraulic | High strength, rigid |

| Plastics | Screw / Pneumatic | Medium strength |

| Rubber | Pneumatic | Uniform pressure |

| Films | Pneumatic | Cannot tolerate serrated jaws |

| Textiles | Capstan | Prevents break at jaw |

| Wire | Wire grip / capstan | Prevents cutting |

| Cable | Wedge cable grip | Strong hold |

| Tape / Adhesive | Peel grips | Standard compliance |

17. Jay Types (Jaw Options)

- Serrated metal jaws → For metals

- Rubber-coated jaws → For soft materials

- Pyramid jaws → For round samples

- V-groove jaws → For wires and thin rods

- Flat jaws → For plates and sheets

18. Maintenance of Grips

- Clean jaws after each use

- Replace worn serrations

- Lubricate mechanical parts

- Check pneumatic systems for leaks

- Inspect hydraulic lines annually

19. Conclusion

Choosing the right grip is not optional—it is the foundation of accurate tensile testing. Whether you’re testing metals, plastics, rubber, cables, or films, the grip must match:

- The material’s mechanical behavior

- Test standard requirements

- Load capacity of the machine

- Shape and thickness of the sample

Correct grips ensure:

- Zero slippage

- No premature breaks

- Accurate tensile values

- Reliable and repeatable results

If you are planning tensile testing for manufacturing, R&D, or quality control, choosing high-quality grips designed for your exact sample type is the smartest investment you can make.