A galvanometer is one of the most essential instruments used in electrical laboratories, research facilities, calibration labs, and industrial testing setups. It is primarily used to detect and measure extremely small electric currents, often in the microampere or even nanoampere range.

Whether you are a student, engineer, physics researcher, electronics manufacturer, or laboratory professional, understanding what a galvanometer is, how it works, and which type you should buy is crucial for accurate measurements.

In this detailed guide, we cover everything you need to know about galvanometers—from the basic principle to types, internal construction, applications, FAQs, price factors, and India’s top manufacturers.

What is a Galvanometer?

A galvanometer is a sensitive electromechanical instrument that detects and measures small electric currents by producing a proportional mechanical movement (usually the deflection of a needle or beam of light).

It operates on the principle that when current flows through a coil placed in a magnetic field, it experiences a torque, causing the pointer to move.

Galvanometers form the foundation of many measuring instruments, such as:

- Analog ammeters

- Analog voltmeters

- Ohm meters

- Null-detection instruments

- Potentiometers

- Wheatstone bridge circuits

- Current balance systems

In modern labs, they are still widely used for precision current detection, especially in educational and R&D setups.

Why Are Galvanometers Important?

Despite digital meters becoming popular, galvanometers remain important because:

- They can detect extremely small currents beyond the sensitivity of basic digital meters.

- They provide instant, real-time deflection, which helps in balancing bridge circuits.

- They are affordable, durable, and require minimal power.

- They help students understand electromagnetic principles practically.

Galvanometers are widely used in electrical labs, physics education, product calibration, material testing, and instrumentation research.

Principle of Galvanometer

Galvanometers work on the motor principle:

When a current-carrying coil is placed in a magnetic field, the coil experiences a torque proportional to the current.

Mathematically,

Torque (T) ∝ Magnetic field (B) × Current (I) × Area (A) × Number of turns (N)

This torque rotates the coil, and the attached pointer moves on a calibrated scale.

Once the current stops, the control springs bring the pointer back to the zero position.

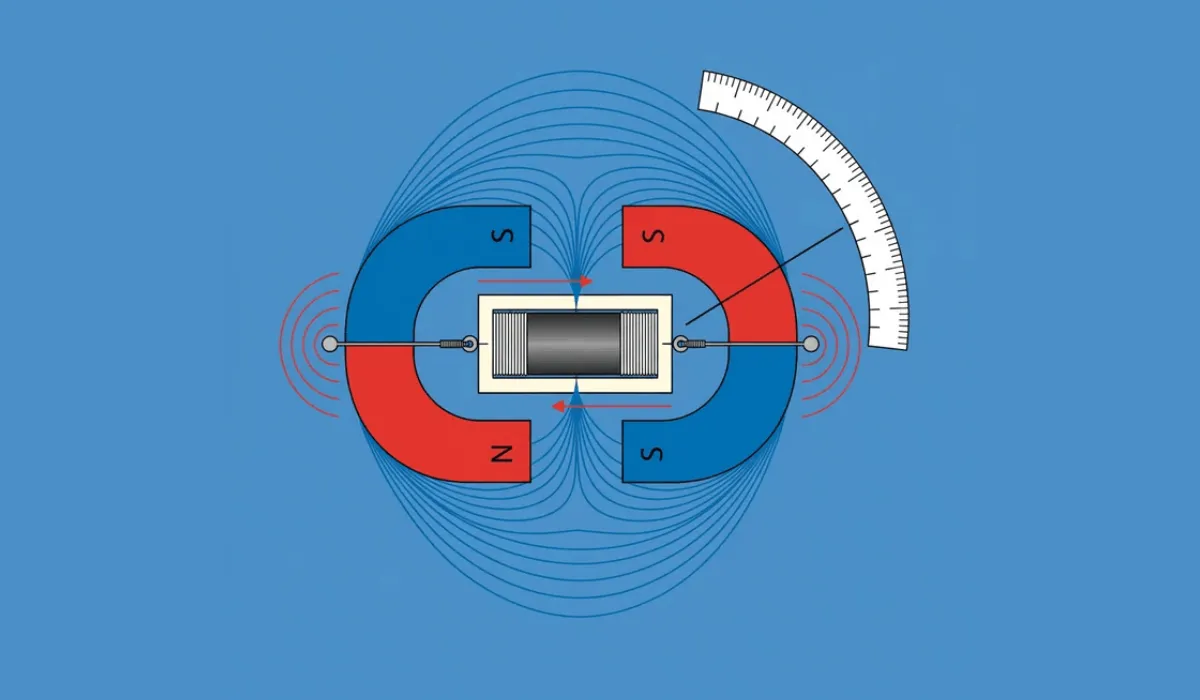

Construction of a Galvanometer

A standard galvanometer consists of the following parts:

1. Moving Coil

- A lightweight rectangular coil with many turns of insulated copper wire.

- Suspended between the poles of a permanent magnet.

2. Permanent Magnet

- Usually a strong high-flux magnet (horseshoe type)

- Provides a uniform radial magnetic field.

3. Suspension / Control System

Includes:

- Phosphor-bronze strips or taut band

- Restoring spring

These generate a restoring torque proportional to deflection.

4. Pointer and Scale

- A lightweight aluminum pointer

- Zero-center or left-zero scale depending on type.

5. Soft Iron Core

- Placed inside the coil to increase magnetic field strength and sensitivity.

6. Damping System

- Usually eddy-current damping with an aluminum frame

- Ensures smooth movement without oscillation.

This construction enables highly sensitive current detection.

Working of a Galvanometer

The operation can be understood in simple steps:

- Current enters the coil.

- The coil experiences a torque due to magnetic field interaction.

- The coil rotates causing the pointer to deflect.

- The deflection is proportional to the current flowing through the coil.

- When current stops, the control spring pulls the pointer back to zero.

The amount of deflection helps determine:

- Direction of current

- Magnitude of current

In physics experiments such as Wheatstone bridge, the galvanometer is used as a null detector, where zero deflection indicates perfect balancing.

Types of Galvanometers

There are several types depending on construction, working principle, and application.

| Feature / Parameter | Moving Coil Galvanometer | Spot Reflecting (Mirror) Galvanometer | Digital Galvanometer |

| Basic Principle | Current-carrying coil rotates in a magnetic field | Light spot reflected from mirror attached to moving coil | Electronic sensing of current using ADC & microcontroller |

| Sensitivity | High (µA range) | Very High (nA–µA range) | Medium to High (depends on electronics) |

| Deflection Indication | Mechanical pointer on a scale | Light spot on a distant screen | Digital display showing numerical value |

| Accuracy | ±1–2% typically | ±0.1–1% (very precise) | ±0.5–1% depending on circuitry |

| Response Time | Fast but can oscillate | Extremely sensitive but slower settling | Very fast |

| Damping Method | Eddy current damping in aluminum frame | Optical system + coil damping | Electronic damping & filtering |

| Best Use Case | Student labs, general current detection | Research labs, null detection, Wheatstone bridge | Industrial use, precise digital readout |

| Current Range | µA to few mA | Nanoampere to microampere | Depends on design (µA to mA) |

| Power Requirement | No external power needed for operation | No external power (light source required) | Requires battery/USB/power supply |

| Durability | Good but coil is delicate | More delicate due to mirror system | Very durable (solid-state) |

| Cost | Low to Medium | Medium to High | Medium to High |

| Ease of Reading | Moderate | Requires a screen & dark room | Very easy (direct numerical output) |

| Conversion to Ammeter/Voltmeter | Easy using shunt or series resistance | Not commonly used for conversion | Already designed for multi-range measurements |

| Parallax Error | Possible | Zero parallax (optical) | None |

| Use in Bridge Circuits | Good | Excellent (most preferred) | Yes, used with Kelvin Double Bridge |

| Overall Suitability | Best for education & basic labs | Best for high-sensitivity research | Best for digital workflows & industrial testing |

Few other types of Galvanometer:

1. Moving Magnet Galvanometer

Here, the magnet moves and the coil is fixed.

Advantages:

- Less friction

- Simple structure

- Used in older analog devices

2. Ballistic Galvanometer

Designed to measure quantity of charge rather than current.

Used in:

- Measuring capacitor discharge

- Induced charge experiments

- Earth inductor coils

- Electromagnetic research

3. Taut-Band Galvanometer

Uses a taut band instead of a suspension wire.

Benefits:

- Zero friction

- Very smooth movement

- High repeatability

Commonly used in quality analog instruments.

4. D’Arsonval Galvanometer

A refined version of moving coil galvanometer.

Features:

- Permanent magnet

- Lightweight coil

- Very high accuracy

Forms the base of most modern analog meters.

Applications of Galvanometer

Galvanometers are used in several industries and lab environments:

1. Electrical & Electronics Laboratories

- Detecting small currents

- Bridge balancing. For Kelvin Double Bridge

- Teaching basic principles

2. Calibration & Testing Labs

- Null detection

- Sensitivity measurement

- Instrument calibration

3. Manufacturing & Production

- Quality testing

- Current monitoring

- Circuit tuning

4. Research Institutions

- Electromagnetism experiments

- Quantum physics setups

- Radiation experiments

5. Education & Training

- Essential for BSc, MSc, Polytechnic & Engineering labs

6. Optical Systems (for mirror galvanometers)

- Telecom

- Laser scanning

- Feedback control

Why a Galvanometer Is Used with a Kelvin Double Bridge?

A galvanometer is an essential part of a Kelvin Double Bridge, which is used for measuring very low resistances such as micro-ohm and milli-ohm values. It works as a high-sensitivity null detector, helping identify the exact balance point of the bridge.

Key Reasons:

✔ 1. Extremely High Sensitivity

A galvanometer can detect very small currents (in microampere range), which is crucial because low-resistance tests produce tiny imbalance currents.

✔ 2. Accurate Null Detection

The Kelvin Double Bridge works on the principle of achieving a balance point. The galvanometer clearly shows the zero-deflection condition, enabling highly accurate resistance measurement.

✔ 3. Shows Direction of Imbalance

The needle deflects left or right, indicating whether the bridge ratio needs to be increased or decreased. Digital meters show this directional feedback by + or – sign.

✔ 4. Low Internal Resistance

A galvanometer does not load or disturb the low-resistance circuit. This helps maintain the stability and accuracy required for micro-ohm testing.

✔ 5. No Electrical Noise or EMI Issues

As an electromechanical device, the galvanometer is immune to digital noise and EMI, ensuring clean and reliable readings.

✔ 6. Ideal for Precision Testing

Because of its sensitivity and noise-free operation, a galvanometer is the preferred choice for laboratory-grade Kelvin Double Bridge systems.

Specifications to Consider Before Buying a Galvanometer

Selecting the right galvanometer is important for lab accuracy.

Here are essential parameters:

1. Sensitivity

Measured in microampere per division (µA/div).

Higher sensitivity = better small-current detection.

2. Coil Resistance

Internal resistance affects circuit behavior and sensitivity.

3. Full-Scale Deflection Current

Amount of current needed for maximum pointer movement.

4. Damping

Should ensure smooth deflection.

5. Calibration Accuracy

Good quality meters offer ±1% to ±2% accuracy.

6. Scale Type

- Linear scale

- Mirror scale to reduce parallax error

7. Build Quality & Materials

High-quality magnets, aluminum pointer system, strong suspension.

8. Application Requirement

Education labs need standard MCG

Research labs or Industry require Digital Galvanometer

How to Choose the Right Galvanometer for Your Lab?

Use this quick selection guide:

| Requirement | Recommended Type |

|---|---|

| Basic student experiments | Moving Coil Galvanometer |

| Bridge & null detection | Spot / Digital Galvanometer |

| Research experiments | Taut-band or Mirror-type or Digital |

| Charge measurement | Ballistic Galvanometer |

| Precision analog indication | D’Arsonval Type |

Advantages of Galvanometers

- Extremely high sensitivity

- Low power requirement

- Quick response

- Real-time deflection

- Easy to understand and operate

- Essential for bridge circuits

- Economical for labs

Limitations of Galvanometers

- Cannot measure large currents directly

- Delicate and requires careful handling

- Affected by temperature and magnetic fields

- Not suitable for AC measurement

Galvanometer vs Ammeter vs Multimeter

| Parameter | Galvanometer | Ammeter | Multimeter |

|---|---|---|---|

| Primary Use | Detect small currents | Measure current | Measures V/I/R |

| Sensitivity | Extremely high | Medium | Medium-high |

| Current Range | µA to mA | mA to A | Depends on model |

| Application | Labs & research | Industrial testing | General-purpose |

Galvanometer Price in India

Prices vary depending on type and sensitivity:

| Type | Price Range (Approx) |

|---|---|

| Student Moving Coil | ₹300 – ₹800 |

| Lab Grade MCG | ₹1,000 – ₹2,500 |

| Ballistic Type | ₹3,500 – ₹9,000 |

| Mirror / Digital Galvanometer | ₹5,000 – ₹12,000 |

| Research Grade | ₹15,000 – ₹30,000+ |

Top Galvanometer Manufacturers & Suppliers in India

Here are some reputed galvanometer manufacturers and lab equipment suppliers:

1. Maxwell Scientific Corporation (India)

- Offers a wide range of educational and laboratory galvanometers

- Supplies to industrial laboratories like cable industry, transformer industry

2. Radical Instruments

- Delhi-based manufacturer of physics laboratory equipment

3. Osaw Industrial Products

- Analog galvanometers but don’t have option for digital ones

4. Ajanta Export Industries

- Specialises in educational lab instruments

5. ESEL International

- Supplier of ballistic, mirror and moving-coil galvanometers primarily for educational institutions

6. Scientific Lab

- Manufacturers for schools & engineering colleges

7. Supertek Scientific

- Known for student-grade galvanometers

8. Shambhavi Impex

- Supplier of research-grade galvanometers

Maintenance Tips for Galvanometers

To ensure long life and stable performance:

- Keep away from strong magnets

- Avoid mechanical shocks

- Store in clean, dry environment

- Use only within specified current limits

- Periodically check zero alignment

Frequently Asked Questions (FAQs)

1. What is the use of a galvanometer?

A galvanometer detects and measures very small electric currents and indicates both magnitude and direction.

2. Can a galvanometer measure voltage?

Not directly.

But by adding high resistance in series, it can be converted into a voltmeter.

3. Can a galvanometer measure high currents?

No.

To measure high current, it must be converted into an ammeter using a low-value shunt resistor.

4. What is a ballistic galvanometer used for?

It is used to measure quantity of charge, such as in capacitor discharge experiments.

5. What is full-scale deflection?

It is the maximum deflection the pointer can achieve when the rated current flows.

6. Why does the galvanometer pointer oscillate?

Due to lack of proper damping.

High-quality galvanometers use eddy current damping to reduce oscillations.

7. What is the difference between mirror galvanometer and spot galvanometer?

Both are similar but:

- Mirror galvanometer uses a light beam for reading.

- Spot galvanometer uses a spot of light on a screen.

8. Is galvanometer still used today?

Yes.

It remains essential in physics education, R&D labs, and precision experiments.

8. Is a galvanometer AC or DC?

A standard moving-coil galvanometer is an instrument designed for use with DC (direct current) only. It cannot effectively measure standard AC (alternating current).

Conclusion

A galvanometer is one of the most fundamental instruments in electrical measurement and physics experimentation. Its ability to detect very small currents makes it invaluable in educational labs, research facilities, calibration centers, and electronics testing environments.

In this guide, we discussed the working principle, types, applications, specifications, price, and manufacturers in India, along with a detailed buying guide and FAQs.

Whether you are setting up a physics lab, upgrading your testing facility, or supplying educational instruments, a high-quality galvanometer ensures accurate and reliable measurements.

2 Comments

A micro-ohm meter is ideal when quick readings are required.

Due to time constraints, it is commonly preferred by laboratory managers.

A Kelvin Double Bridge, on the other hand, is a highly technical instrument that requires expert knowledge to obtain accurate resistance values.

It is primarily used by BIS/RITES inspectors because the measurement method cannot be manipulated to produce incorrect or misleading results.