A hot air oven is one of the most essential pieces of equipment in a laboratory and industrial testing environment. It is widely used for sterilization, drying, curing, heat treatment, ageing tests and thermal stability studies in various industries including pharmaceuticals, microbiology, plastics, rubber, electronics, cable, automotive and research institutions.

Unlike steam-based sterilizers, a laboratory hot air oven uses dry heat and controlled air circulation to achieve uniform temperature throughout the chamber. Depending on the model and configuration, hot air ovens normally operate from ambient + 5°C up to around 150°C, 250°C or even 300°C, making them suitable for a wide range of laboratory and industrial applications.

In this detailed guide, you will learn:

- What a hot air oven is and how it works?

- Common uses in laboratories and industries

- Typical temperature ranges and performance factors

- Relevant IS, ASTM and ISO references

- A complete buying guide

- Approximate price range in India

- Maintenance tips and FAQs

This blog will help you make the right decision while selecting a hot air oven for your laboratory or production line.

What is a Hot Air Oven?

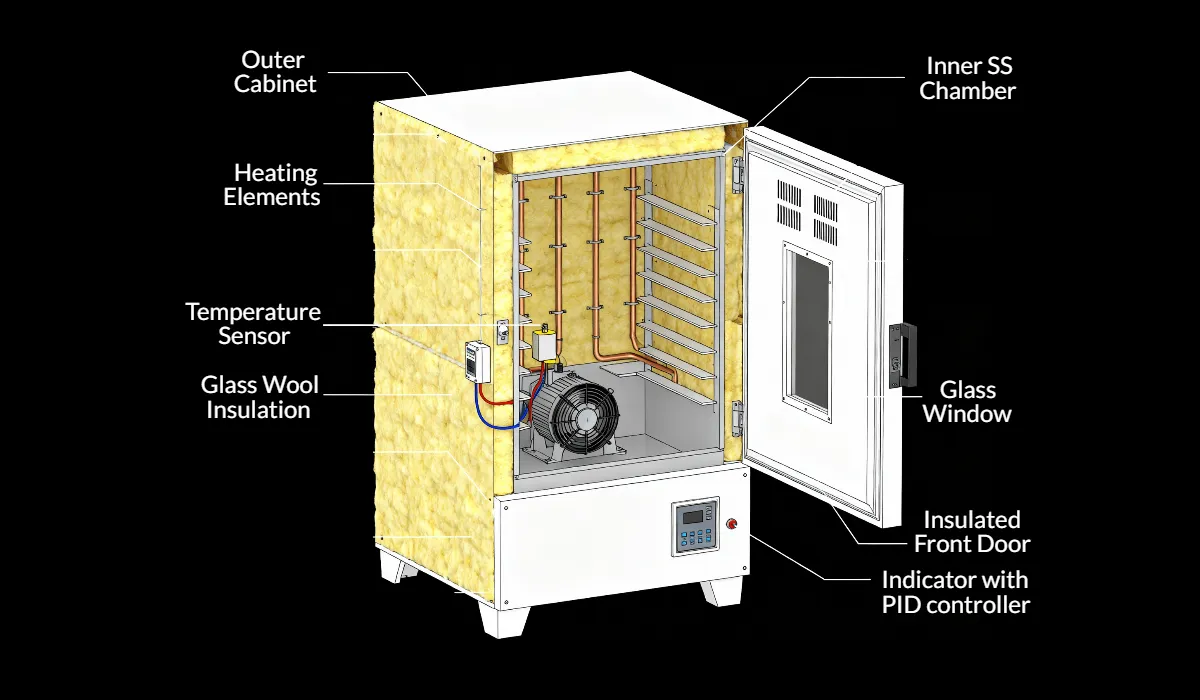

A hot air oven is a laboratory device used to heat, dry and sterilize materials using dry heat convection. Inside the chamber, air is uniformly heated by electrical heating elements and circulated either by natural convection or forced air circulation (fan-assisted) to maintain a consistent temperature throughout the entire chamber.

Hot air ovens are particularly effective for:

- Sterilization of glassware, metal tools, and powders

- Drying wet materials

- Removing moisture from samples

- Curing and heat treatment processes

- Ageing tests for polymers, rubbers and cables

Autoclave vs Hot Air Oven: Unlike an autoclave that uses moist heat (steam), a hot air oven uses dry heat, making it more suitable for materials that may corrode in the presence of moisture or require moisture-free environments.

Working Principle of a Hot Air Oven

The basic working principle of a hot air oven is simple and efficient:

- Electrical heating elements generate heat.

- The heat warms the air inside the chamber.

- A fan (in forced-air models) circulates the heated air uniformly.

- A digital or analog controller maintains the set temperature.

- Thermocouples or RTDs monitor the chamber temperature continuously.

This dry, evenly distributed heat eliminates microbes and dries materials efficiently without introducing moisture. This principle is the reason why hot air ovens are widely used in microbiology labs, testing labs and material research facilities.

Hot Air Oven vs Muffle Furnace (Key Difference)

Many users often confuse a hot air oven with a muffle furnace. While both are used for heating, they have clear differences:

| Feature | Hot Air Oven | Muffle Furnace |

|---|---|---|

| Typical temp range | 50°C to 300°C | 400°C to 1200°C+ |

| Heating medium | Circulating hot air | Radiant heat |

| Main use | Drying, sterilizing, curing | Ashing, calcination, high-temp tests |

| Atmosphere | Air | Can be air or controlled gas |

| Energy consumption | Moderate | High |

A hot air oven is ideal for low to medium-temperature applications, while muffle furnaces are required for extreme temperature environments such as ash content testing, ceramic sintering and metal heat treatment.

Common Uses of a Hot Air Oven

A hot air oven is an extremely versatile instrument. It is used in a wide range of industries and testing environments.

Laboratories & Research Institutes

- Sterilization of glassware such as petri dishes, flasks and test tubes

- Drying of laboratory samples

- Moisture analysis after washing

- Controlled heating of chemicals

Hot air ovens are commonly found in:

- Microbiology labs

- Chemical labs

- Pharma QA/QC departments

- University research centres

Dry heat sterilization is especially useful for glass and metal equipment because there is no moisture residue left on the instruments after sterilization.

Cable & Polymer Testing Industry

Hot air ovens play an important role in cable and polymer testing. They are used in standards related to:

- Heat shock tests

- Hot set tests

- Ageing of insulation and sheath

- Dimensional stability tests

Indian standard IS 10810 and several ASTM/ISO methods use lab ovens for preparing and testing cable samples. These standards specify conditions for thermal ageing and deformation testing inside a controlled temperature oven.

In the cable and plastic industry, ovens are essential for:

- Testing insulation properties

- Simulating long-term ageing

- Studying material degradation at high temperature

Pharmaceutical & Medical Industry

In pharmaceutical manufacturing and testing, hot air ovens are used to:

- Dry glass containers before filling

- Sterilize metal instruments

- Cure coatings on medicinal packaging

- Perform stability tests under controlled heating

They are widely used in hospitals, pharma plants and packaging units as support equipment.

Industrial Applications

Beyond laboratories, hot air ovens are used in:

- Paint curing

- Coating process

- Powder coating preheating

- Automotive part drying

- Electronics PCB drying

Their role in production lines is just as critical as in research facilities.

Temperature Range & Performance

The temperature range of a hot air oven depends on design, insulation quality and heating system.

- Small laboratory models: 50°C to 150°C

- Standard models: 50°C to 250°C

- High-temperature models: Up to 300°C

Some specialized ovens can go even higher for niche applications. Temperature stability and uniformity are key selection criteria for professional testing environments.

Important Terms:

- Temperature Uniformity: How evenly temperature is distributed inside the chamber

- Temperature Fluctuation: Variation from the set value

- Recovery Time: Time to return to set temp after opening door

High-quality hot air ovens maintain tight tolerances (±1°C to ±3°C depending on class).

Important Specifications to Consider

When selecting a hot air oven, consider the following technical factors:

1. Chamber Size & Capacity

Choose based on the size and number of samples you usually process. Common capacities:

- 30 – 50 litres (small labs)

- 90 – 150 litres (medium scale)

- 250 – 500 litres (industrial use)

2. Temperature Range

Make sure the maximum temperature meets your application requirement:

- 150°C (basic labs)

- 250°C (standard testing and sterilization)

- 300°C (advanced material testing)

3. Air Circulation

- Natural convection: Basic use, lower cost

- Forced convection: Better uniformity, faster heating, professional use. Inbuilt fan system should be provided.

4. Controller

- Digital PID controller for precision

- PV(Present Value) & SV(Set Value) of Temperature should be clearly visible on the meter

- LCD/LED display with timer

- Over-temperature protection

5. Chamber Material

- Stainless steel (SS 304) – recommended for lab use or even better SS 316 for applications where acid/chemicals are involved

- Powder Coated Mild steel with internal chamber of SS (for budget applications)

6. Safety Features

- Over-temperature cut-off

- Auto shut-off

- Door safety lock

- Alarm indication

Hot Air Oven Price in India

Hot air oven prices in India vary based on capacity, temperature range and features.

Typical price ranges:

- Small models: ₹10,000 – ₹25,000

- Medium models: ₹25,000 – ₹60,000. For example, Maxwell Hot Air Oven of size 18″ x 18″ x 18″

- Large/industrial models: ₹60,000 – ₹2,00,000+

Digital PID ovens with forced air circulation and higher accuracy fall into the premium category. Prices may also vary based on brand, location and customization level. In India, majorly the manufacturing of Hot Air Oven happens in Ambala (a small town located in Haryana).

Tip: For industrial or calibration labs, investing in a high-quality, uniform, forced-air oven gives better reliability long-term.

Manufacturers of Hot Air Oven

Maxwell – Ambala, Haryana, India

Manufacturer of laboratory hot air oven in Ambala. Known for custom solutions and compliance with Indian and international standards. Click to check Out Now.

Thermo Fisher Scientific – USA (Global presence)

Global leader in scientific equipment, offering high-precision laboratory and hot air ovens. Widely used in pharma, research, and industrial laboratories.

Memmert GmbH & Co. KG – Germany

Premium brand known for highly accurate and energy-efficient laboratory ovens. Preferred in research, pharmaceutical, and university laboratories.

Esco Micro Pte. Ltd. – Singapore

Supplies laboratory and drying ovens for medical, research, and industrial use. Known for compact design and international compliance.

Osworld Scientific Equipments – Mumbai, India

Indian supplier of laboratory instruments including reliable hot air ovens. Used in hospitals, pharma, and quality testing labs.

Hotking Instruments – Chennai, Tamil Nadu

Manufacturer of laboratory and industrial hot air ovens and tray dryers. Also provides customized heating solutions. Manufacturer of laboratory hot air oven in Chennai.

VGS Industrial Oven Manufacturers – Chennai, Tamil Nadu

Specializes in industrial hot air and curing ovens. Offers large-capacity and customized models for industries.

Smart Labtech Private Limited – Hyderabad, Telangana

Supplier of compact laboratory hot air ovens for testing and research. Focuses on precision heating and stability.

Sri Siva Scientific Technologies – Hyderabad, Telangana

Manufacturer of hot air ovens for industrial and educational use. Offers digital control with optional forced air circulation.

Relevant Standards (IS, ASTM, ISO)

Hot air ovens are used in many national and international standards including:

- IS 10810 Part 30 – Methods of test for cables (includes oven ageing, heat shock, hot set tests)

- ASTM D5423 / D2843 – Plastics & polymers

- ISO 188 – Rubber ageing tests

- ASTM E145 – Laboratory oven specifications

Although the standard itself may not be for the oven, the test procedure clearly defines:

- Required temperature range

- Duration

- Placement of samples

- Uniformity and stability requirements

This makes the hot air oven a critical instrument for compliance testing.

How to Choose the Right Hot Air Oven (Buyer’s Guide)

Use this checklist before purchasing:

- ✅ Required maximum temperature?

- ✅ Required internal chamber size?

- ✅ Accuracy and uniformity needed?

- ✅ Natural or forced air circulation?

- ✅ Type of samples (glass, metal, polymer)?

- ✅ Number of shelves/trays?

- ✅ Digital control with timer?

- ✅ After-sales & calibration support?

If your purpose is cable testing or laboratory testing compliance, always choose a forced air digital model with higher uniformity and certification support.

Installation & Operating Tips

To ensure best performance of your hot air oven:

- Place it away from moisture and vibration

- Maintain minimum clearance from walls

- Do not overload trays

- Allow proper air circulation

- Preheat the oven before inserting samples

- Use a thermometer or data logger for validation

Maintenance & Calibration

Maintaining your hot air oven ensures accuracy and long life:

Daily

- Check display readings

- Inspect door seal

- Keep chamber clean

Monthly

- Clean dust from vents and fan

- Inspect power cable

- Check temperature deviation

Yearly

- Calibration by certified NABL lab

- Uniformity testing

- Heater & sensor inspection

Calibration should ideally be performed every 6 to 12 months in quality-critical environments.

Frequently Asked Questions (FAQ)

1. What is a hot air oven used for?

It is used for sterilization, drying, curing, heat treatment and ageing tests in laboratories and industrial applications.

2. What is the typical temperature range?

Most models range from 50°C to 300°C depending on the configuration and models available in Indian market.

3. Can a hot air oven sterilize glassware?

Yes, dry heat sterilization is excellent for glass and metal instruments.

4. What is the difference between hot air oven and autoclave?

Autoclave uses moist heat (steam), while hot air oven uses dry heat.

5. Which standard uses hot air oven in cable testing?

IS 10810 Part 30 includes multiple tests that use laboratory ovens.

6. How often should calibration be done?

Once every 6–12 months is recommended for professional use.

7. What is the difference between a laboratory oven and a hot air oven?

A laboratory oven is a general term that includes different types such as hot air ovens, vacuum ovens, and drying ovens. A hot air oven specifically uses dry heat with air circulation for tasks like sterilization, drying, and ageing tests.

8. Can hot air ovens be used for biological waste sterilization?

No, hot air ovens are not recommended for biological waste. Autoclaves are preferred for biohazard waste as they use steam for more effective sterilization of organic matter.

9. How long does it take for a hot air oven to reach working temperature?

It usually takes 15–45 minutes, depending on:

- Chamber size

- Target temperature

- Heating power

- Type of insulation

Forced-air ovens heat up faster than natural convection models.

10. What is the ideal temperature for sterilizing glassware in a hot air oven?

For effective dry heat sterilization:

- 160°C for 2 hours or

- 170°C for 1 hour

is commonly recommended for laboratory glassware.

11. Can plastic materials be kept in a hot air oven?

Only heat-resistant plastics (such as PTFE or certain industrial polymers) can be placed in a hot air oven. Regular plastics may melt or deform at high temperatures.

12. How do I check temperature uniformity inside a hot air oven?

Uniformity is checked using:

- Multiple thermocouples placed at different locations inside the chamber

- A data logger or temperature sensor array

- Comparing the readings over a fixed time period

This is often done during calibration and validation.

13. Is calibration mandatory for hot air ovens in a testing lab?

Yes. In NABL, ISO, BIS, or ASTM-regulated labs, periodic calibration is required to ensure accurate and repeatable test results.

14. What is the power consumption of a hot air oven?

Power consumption varies:

- Small (40–60L): ~500–800 W

- Medium (90–150L): ~1–2 kW

- Large (250L+): 3–6 kW

It depends on insulation, temperature, and usage pattern.

15. How many trays/shelves are included in a standard hot air oven?

Most models come with 2 to 4 adjustable stainless steel trays, but this can be customized based on user requirements.

16. Can I use a hot air oven for powder coating applications?

Yes, hot air ovens are used for:

- Preheating parts

- Curing powder coating

However, for continuous production, a curing oven or conveyor oven may be more suitable.

17. What safety precautions should be followed while using a hot air oven?

- Do not touch inner walls when hot

- Use heat-resistant gloves

- Avoid overcrowding

- Keep flammable materials away

- Do not block air vents

18. How is a hot air oven different from an incubator?

An incubator typically operates at low temperatures (25–80°C) for biological growth, while a hot air oven operates at high temperatures (up to 300°C) for drying and sterilization.

19. Can a hot air oven be customized?

Yes. Many manufacturers offer:

- Custom chamber sizes

- Higher temperature ranges

- Special airflow designs

- Programmable controllers

- Viewing windows and extra ports

20. What industries commonly use hot air ovens?

- Cable & Wire testing

- Pharmaceuticals

- Food processing

- Automotive

- Electronics

- Research & Education

- Plastics & Rubber

- Packaging

21. How long does a hot air oven last?

With proper maintenance, a good-quality oven can last 8–15 years or even more.

22. Can I use a hot air oven continuously for 24 hours?

Industrial-grade models are built for continuous use, but it’s recommended to:

- Provide ventilation

- Avoid constant max load

- Allow cooling cycles when possible

23. What is the ideal clearance space around a hot air oven?

Minimum recommended clearance is:

- 6–12 inches from walls

- Proper ventilation at back and top

This helps in heat dissipation and improves safety.

24. Are hot air ovens portable?

Small-capacity models (30–60L) are semi-portable. Larger industrial models are heavy and meant for fixed installation.

25. How to set temperature in Hot air oven?

In PID based meters, first the user has to do auto-tuning of the installed meter. After auto-tuning, user can set the Set Value as per the requirement.

Why Choose High-Quality Hot Air Ovens?

Selecting a good hot air oven results in:

- Better test accuracy

- Reliable repeatability

- Long equipment life

- Compliance with standards

- Improved lab safety

Check out: Maxwell Hot Air Oven

For industries working under ISO, BIS, ASTM or NABL environments, equipment quality is not optional — it is mandatory.

Conclusion

A hot air oven is a core laboratory and industrial tool that plays an important role in modern testing, research and production environments. From sterilizing instruments to supporting cable testing as per IS 10810 Part 30, from drying samples to curing materials, it has a wide and essential application range.

By selecting the correct temperature range, chamber size and air circulation type, you can significantly improve your operational accuracy and efficiency. Whether you are a testing laboratory, cable manufacturer, pharmaceutical unit or research institute, investing in a high-quality hot air oven will give you long-term reliability and compliance benefits.

If you are looking for a reliable laboratory hot air oven with excellent performance, durability and after-sales support, click here to explore our range of models on our website or contact our experts for guidance.