Description

Specification Table

-

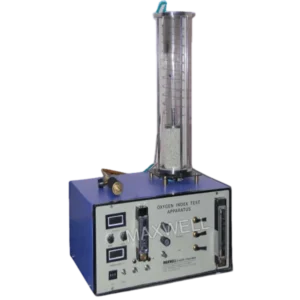

Product Name: Melt Flow Index Tester

-

Model: MFI-623

-

Test Standard: Melt Flow Rate Test for Polymers

-

Temperature Control: PID Controller with 0.1°C Accuracy

-

Test Temperature: Commonly used at 200°C for polyethylene

-

Cylinder Material: Hardened Steel

-

Internal Cylinder Diameter: 9.550 ± 0.025 mm

-

Cylinder Length: >115 mm

-

Heating System: Helically wound heaters; insulated with asbestos bricks

-

Chamber: Hard-chromed for durability

-

Piston Material: Mild Steel with Ebonite Stud

-

Piston Head Dimensions: 6.35 ± 0.1 mm

-

Load: Standard 2.16 kg load provided

-

Application: Polymer melt flow testing (MFI/MFR)

-

Usage: Industrial QC, Production, R&D Laboratories

-

Condition: New

-

Availability: In Stock

Product Description

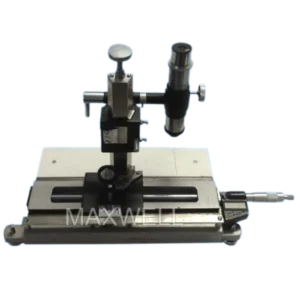

The MFI-623 Melt Flow Index Tester is a high-precision instrument designed to measure the melt flow rate (MFR) of thermoplastics, such as polyethylene and polypropylene. This test helps assess polymer viscosity, flow characteristics, and overall quality—making it a crucial tool for plastic manufacturing, compounding units, and quality control laboratories.

At the heart of the device is a PID temperature-controlled extrusion plastometer, which ensures outstanding temperature stability with an accuracy of 0.1°C. This provides consistent thermal conditions for highly repeatable test results.

The system includes a hardened steel cylinder with a precisely controlled internal diameter and length, helically wound heaters, and high-quality thermal insulation for uniform heating. The mild steel piston, designed with an ebonite stud for load isolation, smoothly applies the standard load (2.16 kg) required for accurate melt flow measurement.

By heating the polymer and measuring the rate at which it flows through a standard die under controlled load and temperature, the apparatus delivers essential data used in polymer grading, material selection, and process optimization.

Key Features

-

High-accuracy PID temperature controller

-

Stable and uniform heating across the cylinder

-

Precision-machined hardened steel components

-

Standard 2.16 kg load for polyethylene MFI tests

-

Hard-chromed chamber for durability and thermal stability

-

Smooth piston motion for consistent extrusion

-

Suitable for MFI and MFR tests

-

Ideal for polymer testing labs and production environments

Applications

Perfect for:

-

Polymer manufacturing

-

Plastic processing industries

-

Quality control laboratories

-

Material testing and R&D facilities

-

Melt flow analysis for PE, PP, and other thermoplastics