Description

Technical Specifications

-

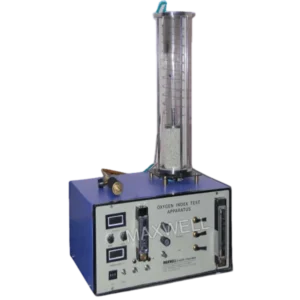

Apparatus Type: 3 Meter Cube Smoke Density Apparatus

-

Standards Compliance: IS:10810 (Part-63) , IEC 61034, BS 6853, BS 6724, BS 7622

-

Internal Volume: 27 m³ (3 m × 3 m × 3 m)

- Internal Finish: Non-reflective black coating

-

Frame Material: Fabricated using square pipe and angle iron, duly powder-coated

-

Light Source: Halogen Lamp – 100 Watt, 12 Volt with a temperature of 2800K

-

Photodetector: Calibrated photo sensor

-

Measurement Range: 0–100% light transmission

-

Resolution: 0.1% of light transmission

-

Optical Path Length: 3 meters

- Optical Assembly: Lamp tube with lens and mirror for precise beam focusing

-

Heat Source: Radiant heater / alcohol burner (as per IS 10810-63 standard)

-

Sample Holder: Heat-resistant tray with 250 grams capacity

-

Flame / Heat Exposure: Controlled and repeatable

- Control System: Real-time display of Light transmission (%), Optical smoke density, Test time & Data logging capability. Computer-based system for real-time analysis and graphical representation (7 Inch HMI model also available)

-

Ventilation & Exhaust: Smoke exhaust fan, ducting provision has to be provided by the buyer

-

Observation Door: Front access door with air-tight seal

-

Windows: 100 mm × 100 mm sealed optical windows on opposite faces

- Enclosure Sealing: Smoke-tight construction to prevent leakage

Product Overview

The 3 Meter Cube Smoke Density Apparatus is a precision test system used to determine smoke emission characteristics of electric cables and materials when subjected to controlled burning conditions. Designed in accordance with IEC 61034 and IS:10810 (Part-63), the apparatus is widely used in fire safety, cable testing, and material evaluation laboratories.

The system consists of a rigid cubic enclosure combined with a high-accuracy photometric system featuring a 3-metre horizontal optical path. During testing, the attenuation of transmitted light caused by smoke is continuously measured, providing reliable and repeatable smoke density data.

Construction & Design

The enclosure is manufactured from black sheets securely fixed to a robust framework, ensuring long service life and dimensional stability. All joints are properly sealed to prevent smoke leakage. A front-mounted access door with a transparent viewing window allows safe visual observation during testing.

Two sealed optical windows positioned on opposite faces of the cube enable accurate photometric measurement. The photocell receiver is housed within a matt black tube to minimize internal reflections and ensure precise light transmission readings.

Photometric & Monitoring System

The photometric system includes a light source and receiver aligned across the full 3-metre width of the chamber. The photocell output signal is directly proportional to the light transmitted through the smoke-filled enclosure and is recorded continuously using either a chart recorder or a computer-based data acquisition system.

To prevent smoke stratification, a floor-mounted fan circulates smoke horizontally throughout the test duration, ensuring uniform smoke distribution inside the chamber.

Features & Benefits

-

Accurate smoke density measurement with 3 m optical path

-

Rugged steel construction with sealed enclosure

-

Continuous real-time data recording

-

Uniform smoke distribution for repeatable results

-

Customizable extraction, instrumentation, and mounting frames

-

Suitable for cable, material, component, and equipment testing

Applicable Standards

-

IEC 61034-1 / IEC 61034-2

-

IS 10810 (Part 63)

Applications

-

Smoke emission testing of electric cables

-

Fire safety and evacuation studies

-

Material smoke density evaluation

-

Research and quality control laboratories

Key Features

-

Fully compliant 3-meter cube design

-

Accurate and repeatable smoke density measurement

-

Robust construction for continuous lab use

-

Easy operation and maintenance

-

Ideal for LSZH and fire-safe cable testing