Description

Specifications

-

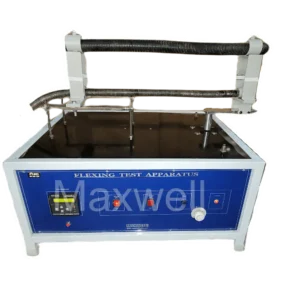

Application: Determination of Vicat softening temperature

-

Penetration Needle: Flat-ended, 1 mm² cross-sectional area

-

Load: 1 kg applied load

-

Sample Thickness: 3–4 mm polyethylene specimens

-

Heating Medium: Glycerol bath

-

Heating Rate: 50°C per hour from room temperature

-

Dial Gauge: Micrometer gauge with 0.01 mm least count

-

Thermal Expansion Tolerance: ≤0.02 mm using low-expansion alloy materials

-

Construction: Recommended low-expansion alloy for structural accuracy

-

Compliance: Meets requirements of IS 10810, Section 22.4.1.4

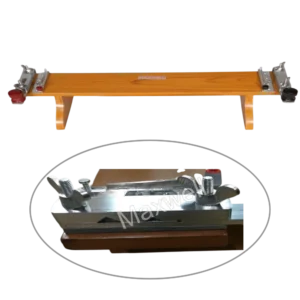

Product Description

The Vicat Softening Point Apparatus is engineered for precise measurement of the temperature at which a polyethylene sample begins to soften under controlled load and heating conditions. Using a standardized 1 mm² flat-ended needle and a 1 kg load, the apparatus determines the point at which the needle penetrates 1 mm into the material, providing a reliable indication of heat-softening behavior.

Designed for laboratory accuracy, the unit features a micrometer dial gauge with 0.01 mm graduations, ensuring exact measurement of penetration depth. The construction uses low-expansion alloy materials, limiting thermal expansion error to less than 0.02 mm across the entire test temperature range. This ensures exceptional repeatability and measurement integrity.

The test is performed in a glycerol bath with a controlled temperature rise of 50°C per hour, enabling consistent and standardized softening point evaluation. Results obtained using this apparatus are ideal for comparing thermal performance of polyethylene and various thermoplastic materials.

This instrument is essential for quality control labs, polymer research centers, and manufacturers seeking accurate heat-softening characterization of plastics.