Description

Specifications

-

Glow Wire Material: Nickel/Chromium (80/20) alloy

-

Wire Diameter: 4 mm nominal

-

Heating Temperature: Up to 960°C

-

Required Current: 120 A to 150 A

-

Force on Specimen: 1.0 N ± 0.2 N

-

Penetration Limit: 7 mm ± 0.5 mm

-

Thermocouple: Class 1 mineral insulated, metal-sheathed (IEC 60584-2)

-

Test Chamber Volume: Minimum 0.5 m³

-

Chamber Condition: Draught-free operation

-

Observation: Clear viewing window to monitor test specimen

-

Standard Compliance: IS 1293, IEC 60695-2-10:2021, IEC 60335, ASTM D 6194-03, IS 4250:1980

Product Description

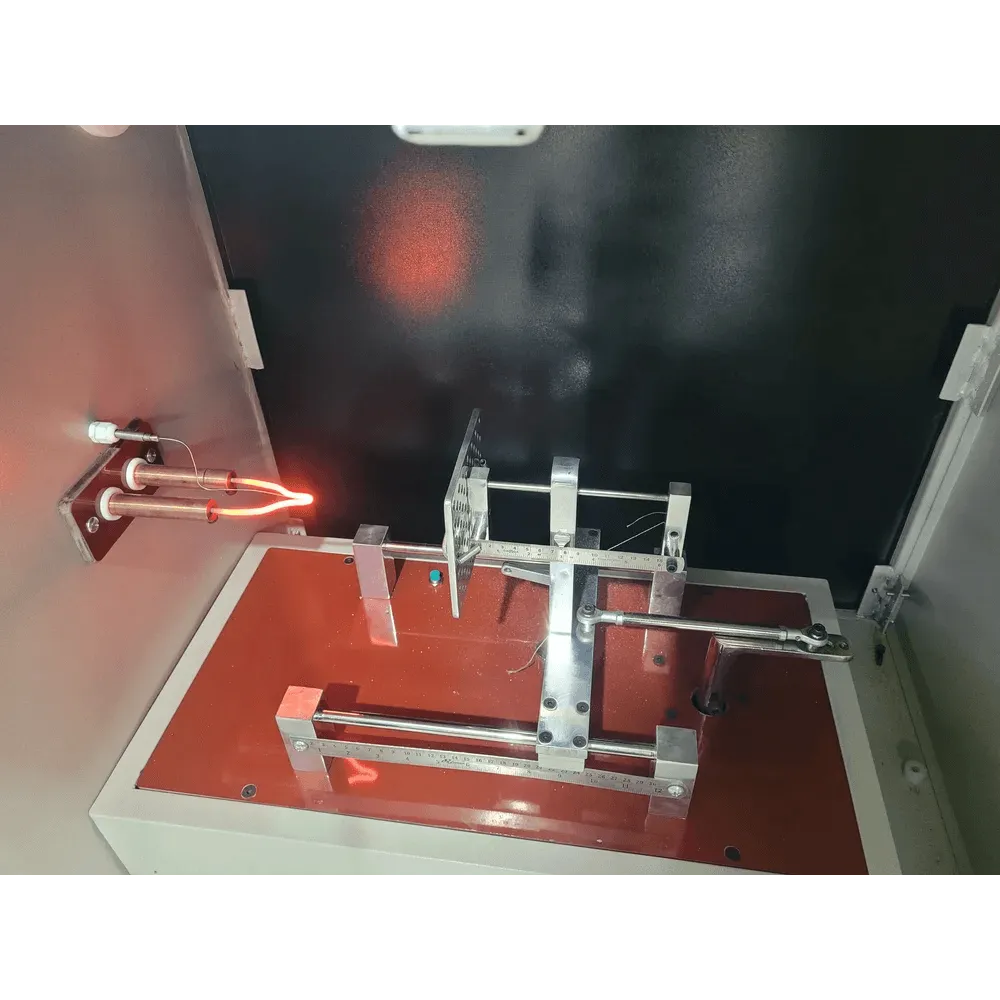

The Glow Wire Test Apparatus is a high-precision testing system designed to evaluate the flame resistance and ignition behavior of electrical components, plastics, and insulating materials under simulated thermal overload conditions. This apparatus is widely used in electrical manufacturing, appliance testing laboratories, polymer industries, and standards certification environments.

The glow wire is constructed from nickel/chromium (80/20) alloy with a 4 mm diameter. It is capable of being heated up to 960°C, requiring a controlled current between 120 A and 150 A. The system ensures accurate and consistent heat delivery without affecting circuit stability.

During testing, the apparatus applies a precise force of 1.0 N ± 0.2 N to the specimen, with penetration strictly limited to 7 mm ± 0.5 mm, ensuring standard-compliant and repeatable results. A Class 1 thermocouple is used to measure tip temperature with excellent accuracy.

The spacious draught-free chamber (≥0.5 m³) prevents external airflow from affecting the results and allows clear observation of flame spread, ignition, or glowing behavior. The chamber design ensures that any burning or molten particles fall safely on the specified layer as per relevant IS/IEC standard.

Built with high-quality components, rugged construction, and advanced safety features, the Glow Wire Test Apparatus delivers reliable, repeatable, and industry-standard flame resistance testing, making it an essential tool for quality control and compliance certification.

Relevant Standards: IS 1293, IEC 60695-2-10:2021, IEC 60335, ASTM D 6194-03, IEC 60598-1, IEC 60947, IEC 60898, IEC 61008-1, IEC 60669-1, IEC 60884-1, IEC 60950-1 / IS 13252, IEC 60238, IEC 60745-1, IEC 60400, IEC 60730-1, IEC 61050, IEC 60320-1, IEC 61058-1 and UL 60745-1, IS 4250:1980