Description

Technical Specifications

1. Test Chamber

- Size: 1000mm Long X 2000mm Depth X 4000mm Height

-

Internal lining: Heat-resistant material

-

Front viewing: Heat-resistant glass window

-

Exhaust system: Chimney / duct for combustion gases

-

Access: Front-opening door with safety latch

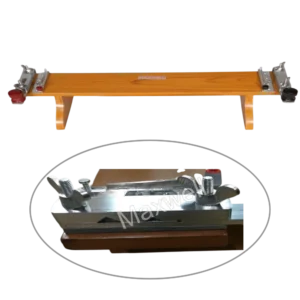

2. Ladder Assembly

-

Material: Stainless Steel

- Ladder 1: 500mm width X 3500mm Height as per fig: 2A of IS:10810 Part(62)

-

Ladder 2: 800mm width X 3500mm height as per fig: 2B of IS:10810 Part(62)

-

Orientation: Vertical

-

Mounting: Suitable for bunched cable installation

3. Burner Assembly

- Two Burners fitted on a Stand of height 600mm will be provided

-

Fuel: Propane / LPG

- Burner is as per Fig: 3A and 3B of IS:10810 Part (62)

4. Gas Supply & Control

-

Gas Type: Propane / LPG

-

Gas Flow Control: Precision regulator and flow control valves

-

Ignition: Auto Ignition System for Each Burner

- Blower inbuilt: To give air into the chamber ranging: 1.0 to 7.0 Cubic Meter/minute

-

Flame stability: Maintained throughout test duration

5. Cable Mounting System

-

Suitable for multiple cable sizes

-

Secure clamping to ensure repeatable test conditions

-

Complies with bunched cable test arrangement

6. Measurement & Observation Control Panel

-

Digital Temperature Indicator Range Ambient to 100°C; LC: 0.1°C, Accuracy:±1° for Chamber temperature

-

Digital Timer Range 99.9 minutes; LC: 0.1 minute and accuracy: ±5 seconds.

-

Digital Air Flow Controller. Range: 0 to 7.00 Cubic Meter/Minute; LC: 0.01 Cubic Meter/minute and accuracy: ±1% of Range

-

LPG Regulator for each burner (i.e. Two Regulators)

-

Air Regulator for each burner (i.e. Two Regulators)

-

LPG Rotameter with Regulator to adjust the Flow Rate. Range: 1 to 12LPM for each burner (i.e. Two Rotameters)

- Air Rotameter with Regulator to adjust the Flow Rate. Range: 10 to 100LPM for each burner (i.e. Two Rotameters)

-

Damage height measurement scale

-

Visual observation through viewing window

Power Requirements

-

Electrical Supply: 230 V AC, 50 Hz

-

Power Consumption: Low (for controls and exhaust fan only)

Safety Features

-

Heat-resistant insulation

-

Flame-safe gas piping

-

Emergency gas shut-off valve

-

Proper ventilation and exhaust system

Accessories Supplied

-

Burner assembly

-

Ladder frame

-

Gas regulator and piping

-

Measurement scale

-

Operating manual

Optional Accessories

-

Propane/LPG gas cylinder

-

Smoke exhaust blower with ducting

Applications

-

Flame retardant cable testing

-

Power, control & communication cables

-

Fire-survival and safety cable evaluation

-

BIS / NABL / third-party inspection laboratories

-

Cable R&D and quality control labs

Key Features

-

Conforms to IEC & IS flame propagation standards

-

Robust and durable construction

-

Accurate and repeatable test results

-

Easy cable mounting and operation

-

Suitable for routine production testing

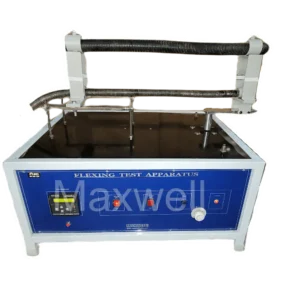

Flame Retardance Test Apparatus for Bunched Cables

(Vertical Flame Propagation Test)

The Flame Retardance Test Apparatus for Bunched Cables is designed to evaluate the flame propagation characteristics of vertically mounted bunched cables when subjected to a standardized flame source. The apparatus complies with IEC, IS and international standards and is widely used by cable manufacturers, test laboratories, and certification bodies.

Applicable Standards

-

IEC 60332-3-10

-

IS 10810 (Part 62)

-

UL 1685

Principle of Test

A bundle of insulated cables is mounted vertically on a ladder inside a metallic chamber and exposed to a controlled flame for a specified duration. After the flame application, the extent of flame spread and damage height is measured to determine compliance with the specified standard.