Description

Specifications

-

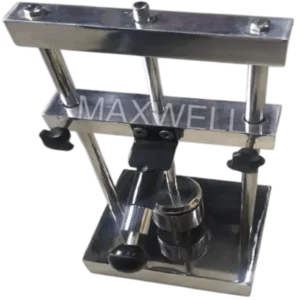

Product Name: Apparatus for Testing Resistance to Abnormal Heat of Insulating Sleeves (Plug Pin)

-

Standard Compliance: IS 1293

-

Application: Testing of insulating sleeves on plug pins

-

Test Temperature: Up to 200°C (standard test at 200°C for 30 minutes)

-

Operation: Heat and pressure endurance testing

-

Specimen Type: Plug pins with insulating sleeves

-

Load Application: Controlled pressure as per IS 1293 test method

-

Heating System: Regulated electric heating unit

-

Duration Control: Accurate test time setting

-

Construction: Rigid heat-resistant structure

-

Dimensions (Approx.): 800 mm x 800 mm

-

Chemical Resistance: Yes

-

Heat Resistance: Yes

-

Power Supply: 220 V AC, 50 Hz

-

Country of Origin: Made in India

Product Overview

The Apparatus for Testing Resistance to Abnormal Heat of Insulating Sleeves (Plug Pin) – IS 1293 is a specialized laboratory instrument used to determine the thermal endurance and safety of insulating sleeves fitted on plug pins. The test evaluates whether the insulation material deforms, softens, or fails when exposed to high temperature under mechanical pressure, ensuring compliance with Indian Standard IS 1293.

During testing, the specimen is subjected to controlled heating (typically up to 200°C for 30 minutes) while a specified load is applied. This process simulates abnormal operating conditions to verify that the insulating sleeve maintains its shape and protective properties without shrinkage or damage.

Designed with an accurate heating system, stable pressure mechanism, and heat-resistant construction, the apparatus provides consistent and repeatable test results. It is widely used by plug manufacturers, test laboratories, certification agencies, and quality control departments to ensure the safety and reliability of electrical plug and socket products.

Key Features & Benefits

-

Fully compliant with IS 1293 testing requirements

-

Controlled high-temperature endurance testing up to 200°C

-

Accurate pressure and time application for reliable results

-

Heavy-duty, heat-resistant construction for long-term use

-

Simple operation and stable performance

-

Ideal for routine quality control and type testing

-

Ensures user safety and product regulatory compliance

Applications

-

Testing of plug pin insulating sleeves

-

IS 1293 product compliance verification

-

Electrical accessory quality assurance

-

Type approval testing laboratories

-

Research and material evaluation centers